Page | 4

TXF

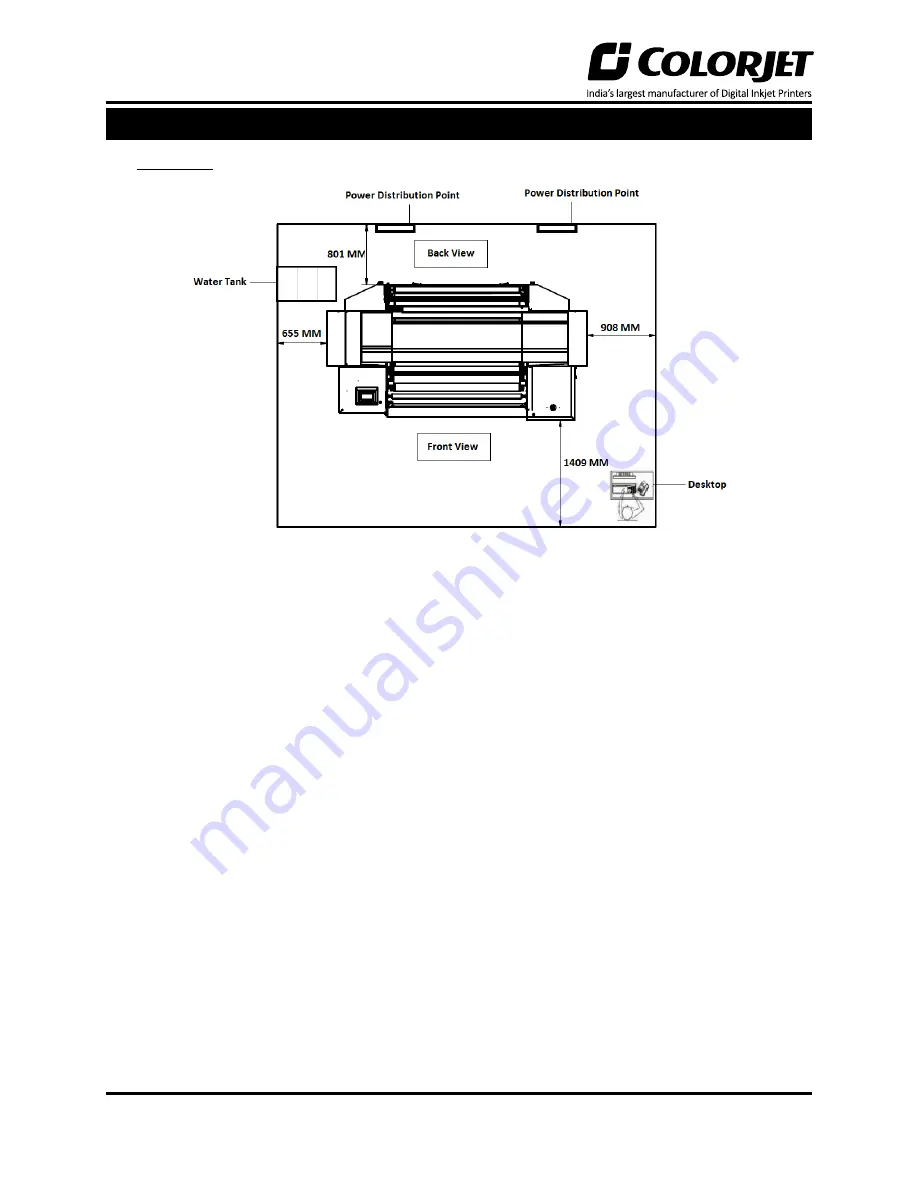

1. Site Layout

The

Site Layout

of the machine is shown in the image below:

Fig 1: Displaying the Site Layout

•

Power Distribution Point 1:

1nos. 16 Amp (Conveyor Belt System) and two MCBs are required

from which one MCB is of 10Amp and other MCB is of 16Amp.

•

Power Distribution Point 2:

3nos. 6 Amp (Print Engine and Computer System).