Page

22

of

39

SubliXpress Plus

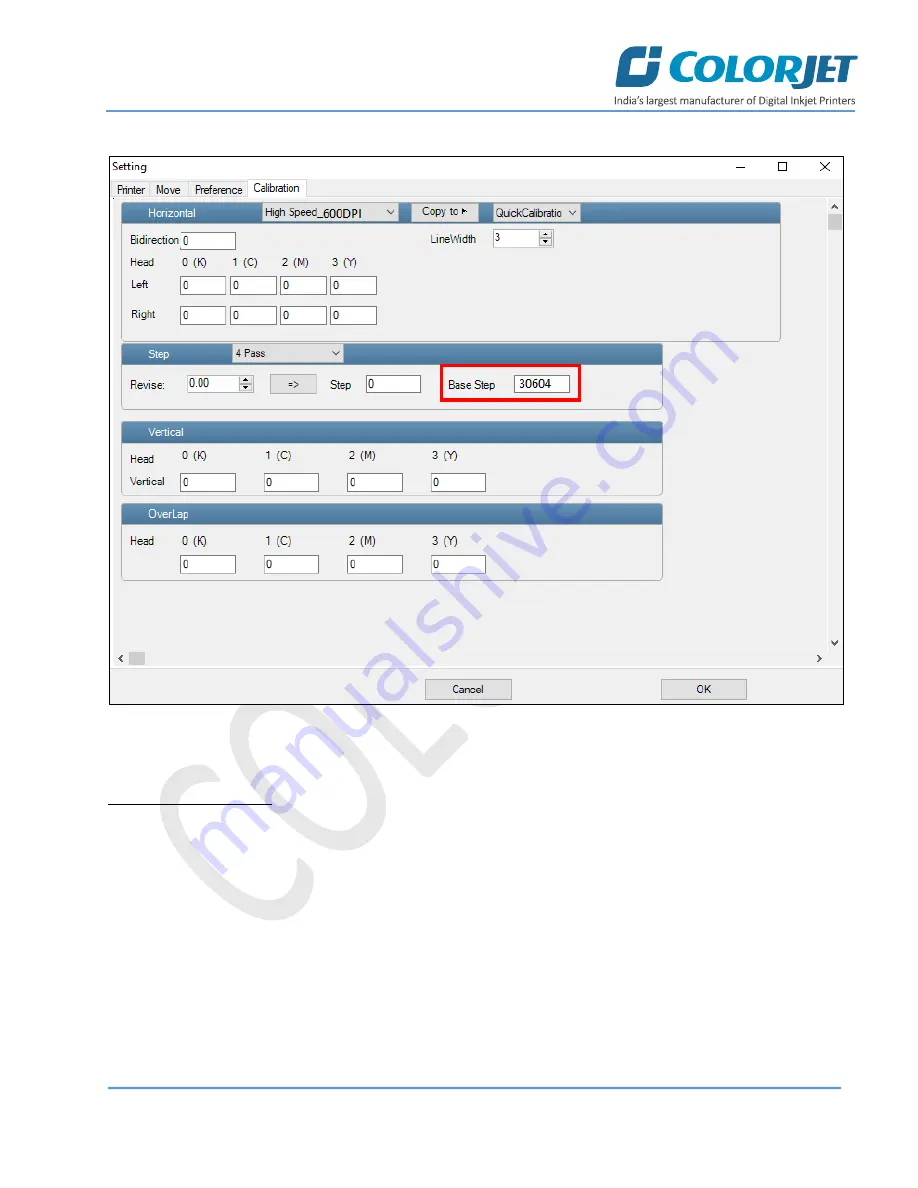

Click on the

Next

button to redirect to the software calibration screen, as shown in the below images:

Fig 25: Displaying the Printer Calibration Options

Note:

Base Step value should be

30583

.

Bi-direction Calibration

Bi-

directional calibration is performed to achieve dot placement accuracy between the “Left to Right” and “Right

to Left” print sweeps. If the bi

-direction offset value is correct, the Left to Right test print would align accurately

with the Right to Left test print at

“0”

position. In case of error in the Bi-Direction offset, the Left to Right and

Right to Left print would align at some other point on the scale.