Page

22

of

50

SOFTJET GRAND

9. Loading Fabric

Follow these steps to load the fabric:

Step 1:

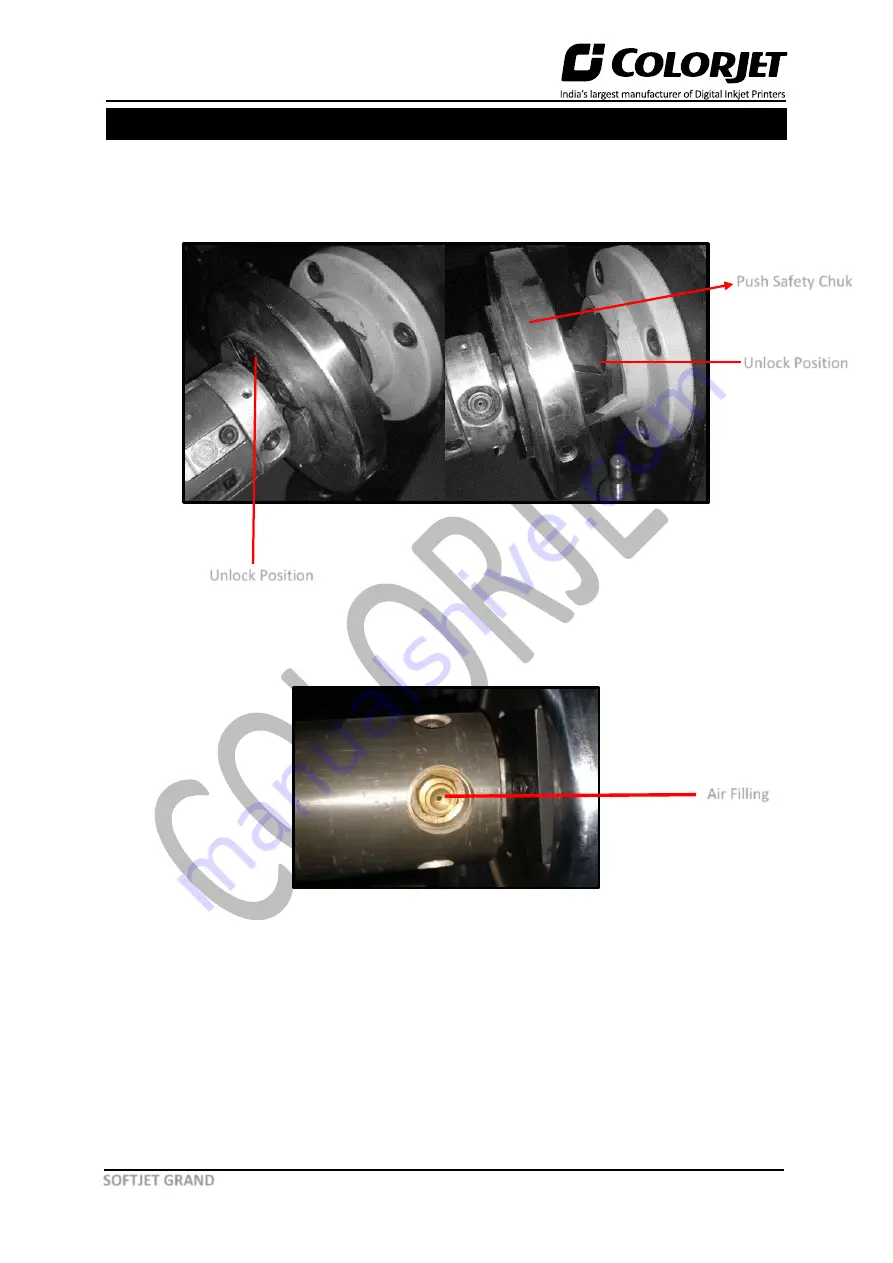

Disengage the Safety Chuk and Shaft by matching the unlock position, as shown in the image

below:

Fig 21: Displaying the Unlock Position

Step 2:

Push the Safety Chuk to remove the shaft.

Step 3:

Insert the shaft into the fabric roll.

Step 4:

After inserting the fabric roll, fill air into the shaft using the Air Gun, as shown below:

Fig 22: Filling Air

Unlock Position

Unlock Position

Air Filling

Push Safety Chuk