Page

4

of

42

SoniQ HQ Plus

1. About Document

Purpose

The purpose of this document is to guide and educate the targeted audience about the Printer and its Printer

Manager software so that they can easily and effectively handle as well as use it as per their requirements.

Additionally, this document also provides step-wise instructions for handling various aspects of the printer and

its related software with the help of graphical screens for easy and better understanding. Moreover, the

document also describes commonly encountered problems while working with the printer and Printer Manager

software with appropriate remedial actions.

Intended Audience

This document is meant for all the users who want to use the Printer for their printing business. Sometimes, the

targeted audience has little knowledge about the printer but in most of the cases, targeted audience is much

familiar with the terminologies of printer and printing business. Thus, this document is designed to facilitate both

types of users.

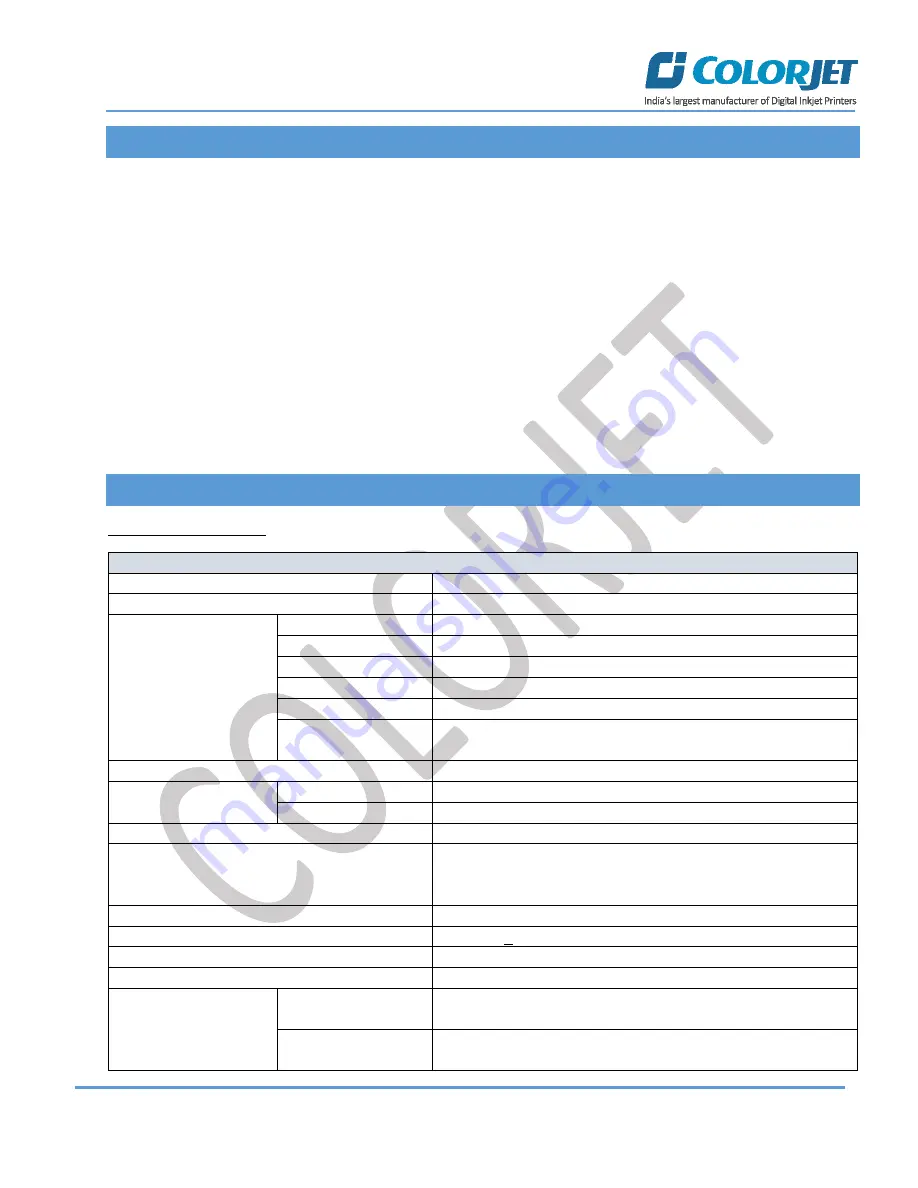

2. Machine Specifications

Machine Specifications

are shown in the table below:

SoniQ HQ Plus (S4427)

Printing Technology

Drop on demand, Piezo Electric Inkjet

Print Heads

Industrial Grade Jetting Assemblies

Media

Width

3300 mm (129 in)

Thickness

Maximum 3.0mm (120 mil) with liner (Flexible)

Roll Outer Diameter

Maximum 300 mm (12 in), 50.8 (2 in)

Roll Weight

Maximum 90 kg

Core Diameter

76.2 mm (3 in)

Type

SAV, PAV Banner, Backlite Film, Window Film, Fabric (Solvent

Base)

Printing Width

Maximum 3200 mm (126 in)

Ink

Type

Solvent/Mild Solvent inks

Colors

4 Colors (CMYK)

Printing Resolutions (DPI)

Maximum 1440 dpi

Media Heating

Pre-heater and post-heater, setting range for the preset

temperature: 30 to 60 Degree Celsius. Dryer setting range for

the preset temperature: 30 to 60 Degree Celsius

Connectivity

High Speed USB

Power Requirements

AC 220 V +10%, 20Amps, 50/60 Hz

Dimensions

4525 x 885 x1500 mm (LxWxH)

Weight (approx. with stand)

642 kg

Environmental

Power ON

Temperature: 18 to 28 Degree Celsius

Humidity: 20 to 80 % RH (Non-Condensing)

Power OFF

Temperature: 5 to 40 Degree Celsius

Humidity: 20 to 80 % RH (Non-Condensing)