Model SH-2012AH-QG

Cutting Machine

(

C002

)

29

auxiliary commands.

Lifting delay of piercing torch

——

The time delay when M72 command is executed, in second. Refer to 6.4 for M

auxiliary commands.

Lowering delay of piercing torch

——

The time delay when M73 command is executed, in second. Refer to 6.4 for M

auxiliary commands.

Piercing delay

——

Lowering delay of cutting torch when M07 is executed in flame piercing operation after cutting

oxygen valve is opened.

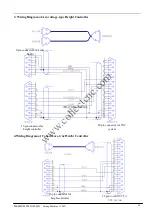

7.4. Plasma Parameters Setting

In the SETUP submenu, press [F4] key to enter plasma parameters setting window, as shown in Fig. 7.5.

Positioning delay of cutting torch-----

When positioning the plasma torch, lower the torch until it hits the lower limit siwtch. Turn on the

torch lifting switch. After count the positioning delay of cutting torch, the lifting torch will stop(M75), in second.

M commands for arc ignition-----

To set the output port of arc ignition, M12 by default

M commands for arc breaking-----

To set the output port of arc breaking, M13 by default

Notes:

When the M command for arc breaking is next higher than the M command for arc ignition, it implies they share an output port, even

number for opening and even number for closing. In this case, the system uses level control to direct arc ignition switch. When the M

command for arc breaking and the M command for arc ignition are both even number but unequal to each other, it implies there are two

output ports separately control the opening and closing operations. In this case, the system uses pulse control with pulse width of 0.5

second.

Arc voltage test option-----

It is used to determine if arc voltage is tested or not in plasma cutting operation. To enable arc voltage test,

take 1 for the option. User should test arc voltage feedback at arc ignition and monitor the feedback in operation. When arc voltage

feedback is off, the system will pause the operation and prompt. As a general rule, arc voltage test is enabled for thick plate machining.

To disable arc voltage test, take 0 for the option. After the arc ignition switch is turned on, the machining will start when the piercing

delay is up. The system will not test arc voltage feedback in the cutting process. Generally, arc voltage test is disabled for thin sheet

machining.

Positioning test option-----

In execution of M07 command, it is used to determine torch positioning operation or not. If the option is

taken 1, torch positioning operation will be enabled.

Piercing delay-----

If arc ignition is successful, the system will start normal cutting operation after the piercing delay.

Height control disabling distance at corner

----- At the transition or corner of two program segments, speed and arc voltage might

change, causing unexpected nozzle knock; therefore, the system will automatically disable the height control in such a distance from the

endpoint of program segment, in mm.

Arc voltage disabling distance near end point

----- The machining path is usually a closed curve. At the end of machining, the origin

point and the end point will repeat, which often cause overburn and affect the smoothness. If this distance option is enabled, the system

will automatically disable the arc voltage and the height control in such a distance from the endpoint , in mm.

www.collectcnc.com