16

Motor Component Testing and Inspection

ELECTRIC VEHICLE - MOTOR

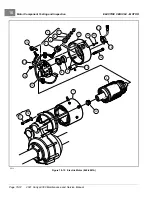

MOTOR FRAME AND FIELD WINDINGS INSPECTION

1.

Remove the motor from the vehicle.

See Motor Removal on page 16-4.

2.

Remove the and cap and armature by performing steps 1 through 7 of Motor Disassembly on page 16-6.

3.

Burned or scorched insulation on the field windings indicates the motor has overheated due to overloads or

grounded or shorted coil windings. If the insulation on the field windings is scorched, replace the motor or

the stator shell assembly.

MOTOR BRUSH, SPRING, AND TERMINAL INSULATOR INSPECTION

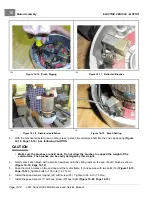

Brush Spring Tension Test

1.

Remove the motor from the vehicle.

See Motor Removal on page 16-4.

2.

Remove the end cap and armature by performing steps 1 through 7 of Motor Disassembly on page 16-6.

3.

Inspect the brush springs (14)

. Replace springs that are discolored from heat

(light gold or blue tinted).

4.

Test the brush springs for proper tension.

4.1.

Place a C-shaped steel plate on a scale.

4.2.

Place the end of the C-shaped plate so that it is between the spring and the brush as shown

.

4.3.

Gently pull the scale to obtain the spring tension reading.

See following CAUTION.

CAUTION

• When checking brush spring tension, do not over-extend the spring. Using excessive force will

damage the spring.

4.4.

Replace springs which require a force of less than 35 ozf (0.99 kgf)

.

See

following NOTE.

NOTE:

When installing new brushes, remove and replace brushes one at a time. This method ensures the terminals

and brushes will be properly positioned in the rigging. Refer to

for brush

installation.

When replacing brushes, replace all four brushes. Never replace only two.

Install the brushes in the same rigging 180° apart from each other.

Brush Inspection

1.

Remove the motor from the vehicle.

See Motor Removal on page 16-4.

2.

Remove the end cap and armature by performing steps 1 through 7 of Motor Disassembly on page 16-6.

3.

Inspect the brushes (13) for damage or excessive wear

. Replace brushes if required.

See preceding NOTE.

4.

Use dial calipers or a micrometer to measure the brush length. The minimum-allowable brush length is 0.62

inches (16 mm). Replace the set of brushes as required.

See preceding NOTE.

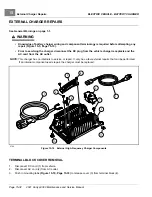

Terminal Insulator Inspection

1.

Remove the motor from the vehicle.

See Motor Removal on page 16-4.

2.

Remove the terminal insulators by performing steps 1 through 12 of Motor Disassembly on page 16-6.

3.

Inspect the insulators (4 and 6) for cracks or other damage

. Replace insulators

as required.

Page 16-10

2021 Carryall 300 Maintenance and Service Manual

Summary of Contents for Carryall 300 2021

Page 2: ......

Page 16: ......

Page 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Page 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Page 566: ...Page intentionally left blank...

Page 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Page 568: ...Page intentionally left blank...

Page 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Page 570: ...Page intentionally left blank...

Page 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Page 572: ...Page intentionally left blank...

Page 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Page 574: ...Page intentionally left blank...

Page 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Page 576: ...Page intentionally left blank...

Page 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Page 578: ...Page intentionally left blank...

Page 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Page 580: ...Page intentionally left blank...

Page 588: ...NOTES...

Page 589: ...NOTES...

Page 590: ...NOTES...

Page 591: ...NOTES...

Page 592: ...NOTES...

Page 593: ...NOTES...

Page 594: ...NOTES...

Page 595: ......

Page 596: ......