ELECTRIC VEHICLE - BATTERY CHARGER

Test Procedures

15

3.

With a multimeter set to 500 volts AC, check incoming AC voltage. Insert multimeter test probes into AC wall

outlet; voltage should be between 85 and 270 volts.

See AC Input Voltage Detection on page 15-4.

If proper

voltage is not present, have building wiring checked by a licensed electrical contractor.

4.

If the charger will not power ON, check AC cord connections.

5.

If the charger is connected correctly, check continuity of the AC cord wires.

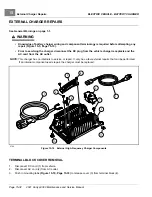

TEST PROCEDURE 6 – Charger DC Circuit Continuity Test

1.

Disconnect the AC cord from the wall outlet and the DC cord from the vehicle charger receptacle.

2.

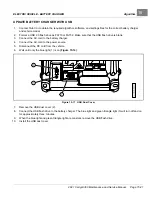

Remove DC terminal block cover.

See Terminal Block Cover Removal on page 15-32.

3.

Note polarity and loosen screws securing DC cord wires. Pull wires from DC terminals on charger.

4.

Check continuity of the DC cord wires from plug pin to fork terminal.

5.

When finished, attach DC cord white wire to positive terminal (+) and black wire to negative terminal (–) with torx

screws.

See following NOTE.

Tighten torx screws to 39.8 in·lb (4.5 N·m).

NOTE:

The positive symbol (+) and negative symbol (–) are molded into the terminal block for easy identification.

6.

Install terminal block cover.

See Terminal Block Cover Installation on page 15-33.

TEST PROCEDURE 7 – Charger Output Test

Without a Meter:

Connect DC cord and start a charge cycle. If buzzer sounds three times, then charger is functioning.

Both a confirmed connection with the charger and a rise in battery pack voltage are required for buzzer to sound

three times.

See following NOTE.

NOTE:

The number of flashes and beeps can vary depending on the Beep Option setting.

With a Meter:

A clamp meter can be used to measure current in the red battery cable (connected to the positive (+)

post of battery no. 1) while charging. Current can reach just over 13-amps at the beginning of a charge session

and taper down to approximately 5-amps near the end.

2021 Carryall 300 Maintenance and Service Manual

Page 15-31

Summary of Contents for Carryall 300 2021

Page 2: ......

Page 16: ......

Page 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Page 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Page 566: ...Page intentionally left blank...

Page 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Page 568: ...Page intentionally left blank...

Page 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Page 570: ...Page intentionally left blank...

Page 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Page 572: ...Page intentionally left blank...

Page 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Page 574: ...Page intentionally left blank...

Page 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Page 576: ...Page intentionally left blank...

Page 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Page 578: ...Page intentionally left blank...

Page 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Page 580: ...Page intentionally left blank...

Page 588: ...NOTES...

Page 589: ...NOTES...

Page 590: ...NOTES...

Page 591: ...NOTES...

Page 592: ...NOTES...

Page 593: ...NOTES...

Page 594: ...NOTES...

Page 595: ......

Page 596: ......