15

Test Procedures

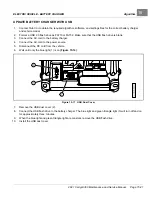

ELECTRIC VEHICLE - BATTERY CHARGER

3.1.

Verify that the 10-gauge red wire from the charger receptacle is connected to the large post of solenoid

with 6-gauge red wire

3.2.

Verify that the 10-gauge black wire from the charger receptacle is connected to the B- terminal of controller.

3.3.

Verify that the 16-gauge light blue wire from the charger receptacle is connected to the light blue wire bullet

connector from the main wire harness.

4.

With batteries connected, DC cord disconnected, and using a multimeter set to 200 volts DC, place the black

(–) probe in the charger receptacle socket connected to the black 10-gauge wire and place the red (+) probe in

the charger receptacle socket connected to the red 10-gauge wire. The reading should be 48 to 50 volts (full

battery voltage).

5.

If the reading is not 48 to 50 volts, check the following items:

– The 30-amp fuse (located near solenoid) in the 10-gauge red wire of the charger receptacle harness.

– Continuity of the 10-gauge red wire from the solenoid to the receptacle socket.

– Continuity of the 6-gauge red wire from the positive post of battery no. 1 to the solenoid.

TEST PROCEDURE 3 – Battery Condition Using Charger

The easiest way to monitor the condition of a vehicle’s batteries is simply to observe the Charger Status Indicators

on the charger at the end of the charge cycle. After a full charge, disconnect the charger DC plug, wait 30 seconds

and reconnect the charger DC plug. The battery-shaped status indicator will be green with the upper half flashing at

first and then stay on continuously within 10 to 20 minutes, indicating sound, fully charged batteries.

Charger Status Indicators on page 15-4.

NOTE:

Batteries near the end of their useful lives may not allow the battery charge current to taper and the upper half

of the battery-shaped status indicator will continue to flash.

Section 14 — Electric Vehicle - Batteries

Continued poor performance may indicate a problem in the vehicle electrical system, brakes or battery charger. If the

problem is not found in the vehicle or charging system, proceed to the on-charge voltage test. If the upper half of

the battery-shaped status indicator does not stop flashing, the batteries should be tested further using the on-charge

voltage test.

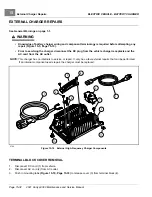

TEST PROCEDURE 4 – On-Charge Battery Voltage Using Charger And Multimeter

When the batteries are fully charged, disconnect the charger DC plug. Wait 20 to 30 seconds and reconnect the DC

plug to restart the charger. After 5 minutes, use a multimeter to check and record the voltage of the battery set as

well as the individual batteries. Set the multimeter to 200 volts DC. Place the red (+) probe on the positive (+) post

of battery no. 1 and the black (–) probe on the negative (–) post of battery no. 6 (for 6 x 8-volt battery set). Record

reading. Then set multimeter to 20 volts DC and place the red (+) probe on the positive (+) post and the black (–) probe

at the negative (–) post of each battery. Record the readings.

The on-charge voltage for the set should be between 56.0 and 63.0 volts depending on the age and state of charge of

the batteries being tested.

Old batteries may have enough capacity left to last several more months.

TEST PROCEDURE 5 – AC Power and Continuity Test of AC Circuit

1.

Disconnect AC cord from the wall outlet and DC plug from the vehicle receptacle.

2.

Check the AC line fuse or circuit breaker in the storage facility.

Page 15-30

2021 Carryall 300 Maintenance and Service Manual

Summary of Contents for Carryall 300 2021

Page 2: ......

Page 16: ......

Page 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Page 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Page 566: ...Page intentionally left blank...

Page 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Page 568: ...Page intentionally left blank...

Page 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Page 570: ...Page intentionally left blank...

Page 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Page 572: ...Page intentionally left blank...

Page 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Page 574: ...Page intentionally left blank...

Page 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Page 576: ...Page intentionally left blank...

Page 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Page 578: ...Page intentionally left blank...

Page 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Page 580: ...Page intentionally left blank...

Page 588: ...NOTES...

Page 589: ...NOTES...

Page 590: ...NOTES...

Page 591: ...NOTES...

Page 592: ...NOTES...

Page 593: ...NOTES...

Page 594: ...NOTES...

Page 595: ......

Page 596: ......