Chapter 2 — Burner Operation and Control

2-14

Part No. 750-184

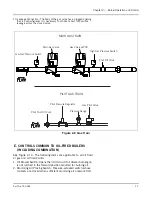

B. Hot Water Oil Heater Thermostat: Used on a hot water boiler to sense

fuel oil temperature and control the starting and stopping of the

booster water pump.

C. Booster Water Pump: Started and stopped by the hot water

thermostat to regulate the flow of hot water through the hot water oil

heater to maintain temperature of fuel oil.

D. Fuel Oil Thermometer: Indicates temperature of fuel oil being

supplied to the fuel oil controller.

E. Back Pressure Valve: For adjustment of oil pressure on the

downstream side of the metering valve. Also regulates rate of return

oil flow.

F. Oil Return Pressure Gauge: Indicates oil pressure on the return side

of the fuel oil controller.

G. Manual By-Pass Valve: Provided as a time saver in establishing oil

flow. When open, it permits circulation of oil through the supply and

return lines. The valve

must

be closed prior to initial light off.

H. Orifice Oil Control Valve: Valve may be opened prior to start-up to aid

in establishing fuel oil flow through the controller. The valve must be

closed prior to initial light off. Its disc has an orifice to permit a

continuous circulation of hot fuel oil through the controller.

I. Air Purge Valve: Solenoid valve opens simultaneously with closing of

oil solenoid valve at burner shutdown, allowing compressed air to

purge oil from the burner nozzle and adjacent piping. The oil is

burned by the diminishing flame, which continues burning for

approximately 4 seconds after the oil solenoid valve closes.

J. Air Purge Orifice Nozzle: Limits purging air to proper quantity for

expelling unburned oil at normal delivery rate.

K. Air Purge Orifice Nozzle Filter: Filters the purging air of any particles

that might plug the air purge orifice nozzle.

L. Air Purge Check Valve: Valve check prevents fuel oil from entering the

atomizing air line.

M.Air Purge Relay: When energized, controls operation of air purge

valve.

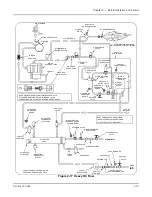

G. CONTROLS FOR COMBINATION BURNERS ONLY

Burners equipped to burn either oil or gas include equipment for

each fuel. The selector switch engages the appropriate interlocks

and controls for gas or oil operation.

H. COMBUSTION AIR

Air for combustion of fuel (often referred to as “secondary” air) is

furnished by the forced draft fan mounted in the boiler head. In

operation, air pressure is built up in the entire head and is forced

through a diffuser plate for a thorough mixture with the fuel for

proper combustion. The supply of secondary air to the burner is

governed by automatically throttling the output of the fan by

regulating the rotary air damper. The damper provides the proper

Summary of Contents for CB Ohio Special 100 HP

Page 2: ...ii ...

Page 8: ...viii ...

Page 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Page 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Page 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

Page 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Page 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Page 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Page 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Page 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Page 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Page 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Page 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Page 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Page 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Page 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Page 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Page 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Page 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Page 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Page 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

Page 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Page 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Page 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Page 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Page 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Page 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Page 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Page 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Page 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Page 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Page 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Page 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Page 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Page 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Page 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Page 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...