Chapter 2 — Burner Operation and Control

2-12

Part No. 750-184

G. Lube Oil Cooling Coil: Cools the lubricating oil before it enters the

air pump. A fan driven by the air pump motor circulates cooling

air over the coil.

H. Lube Oil Fill Pipe and Strainer: Used when adding oil to the air-oil

receiver tank.

13.Low Oil Pressure Switch (Optional): Switch contacts open when

the fuel oil pressure drops below selected pressure. Switch will

interrupt the limit circuit upon loss of sufficient fuel oil pressure

for correct combustion.

14.Fuel Oil Pump: Transfers fuel oil from the storage tank and

delivers it under pressure to the burner system.

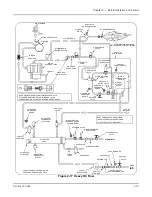

F. ADDITIONAL CONTROLS FOR HEAVY OIL

An oil heater is provided to heat heavy oil to the point where it can

be effectively atomized and burned. Most heavy oil heaters utilize

an electric heater to reduce the viscosity of the heavy oil until the

point where either steam or hot water is available. Heavy oil heaters

operating with hot water will have additional controls not shown

here.

Heater Switch (Not Shown): Manually provides power to the oil

heater system.

1. Oil Heater (Electric): Used for heating sufficient fuel oil for low-

fire flow during cold starts before steam or hot water is available

for heating. The heater must be turned off during extended boiler

lay-up, or at any time the fuel oil transfer pump is stopped.

2. Electric Oil Heater Thermostat: Senses fuel oil temperature and

energizes or deenergizes the electric oil heater to maintain

required temperature of the fuel oil.

3. Steam Oil Heater Thermostat: Senses fuel oil temperature and

controls the opening and closing of the steam heater valve to

maintain the required temperature of the fuel oil.

4. Oil Heater Shell (Steam/Hot Water): Heats fuel oil through

medium of steam or hot water. Electric heater is housed in the

steam heater, but is housed separately on a hot water heater.

Steam oil heaters on 15 psi boilers operate at boiler pressure.

Steam oil heaters furnished on high pressure boilers are to be

operated at less than 15 psi. Operation is accomplished with a

steam pressure regulator valve.

5. Oil Return To Tank: Excess oil returned to the heavy oils supply

tank.

6. Oil Inlet From Supply Tank: Heavy oil inlet from the supply tank.

7. Steam Heater Check Valve: Prevents oil contamination of the

waterside of pressure vessel should any leakage occur in the oil

heater.

8. Steam Trap: Drains condensate and prevents loss of steam from

the steam oil heater. Condensate must be piped to a safe point

of discharge.

9. Check Valve (Steam Heater Discharge): Prevents air entry during

shutdown periods when cooling action may create vacuum

within steam heater.

10.Steam Heater Pressure Regulator: Adjust to provide reduced

(usually less than 15 psi) steam pressure to the heater to

Summary of Contents for CB Ohio Special 100 HP

Page 2: ...ii ...

Page 8: ...viii ...

Page 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Page 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Page 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

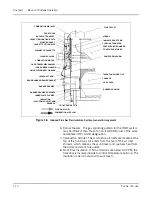

Page 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Page 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Page 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Page 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Page 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Page 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Page 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Page 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Page 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Page 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Page 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Page 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Page 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Page 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Page 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Page 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

Page 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Page 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Page 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Page 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Page 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Page 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

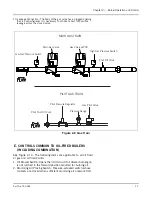

Page 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Page 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Page 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Page 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Page 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Page 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Page 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Page 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Page 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Page 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...