Direct: 763.476.6866 • National: 800.422.2537 • www.SeeClearfield.com • [email protected]

10

YOURx Flex Box

Installation Manual

_________________________________________________________

Manual 019209 REV F - Jan 2019

Drop wheels easily deploy by extending the wheel from the mounting

cradle, pulling the fiber through the microduct, and then assembling the

pulled connector.

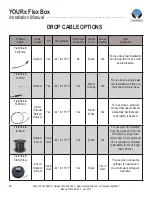

Characteristic

Specification

Material

Black Thermoplastic

Fiber

200 Feet of FieldShield StrongFiber

Connectors

Pullable SC/APC to Standard SC/APC

1. Mount Drop Wheel cradle into appropriate mounting holes (previous page),

mounting the block of Drop Wheels with the fiber termination ports oriented at

the top of the Drop Wheel cradle as shown in (

Figure 1

).

Note:

Fiber peels off to the back of the wheel

.

2. Pull/extend desired wheel forward (

Figure 1

), carefully remove tape holding

the fiber in place (

Figure 2

).

3. Loop a half hitch knot around the connector at the first notch in the crimp tube,

tie the microduct pull string to the connector pulling eye (

Figure 3

).

4.

Feed the connector into the microduct, and with the drop wheel extended,

carefully pull the fiber through the microduct (

Figure 4

).

Figure 1

Figure 2

Figure 3

Figure 4