Scrub System

42

Service Manual – Clarke CA30 20B and 17E

Troubleshooting

Brush Motor (17E)

Caution! If the brush motor does not reach normal operating speed within a few seconds of receiving power,

immediately disconnect power to prevent further damage to the motor. Prolonged high-amperage

current through the windings can permanently damage the motor.

The brush motor is a capacitor-start/capacitor-run induction motor. The two primary failure-modes of this

type of motor are when it’s not receiving any power, or when the start circuit is not functioning properly.

During normal operation, you should hear 2 clicks as the motor starts and stops. The first click is the scrub

relay providing power to the motor, and the second click is the start relay disconnecting the start capacitor.

This is reversed when the motor shuts down. If the second click isn’t heard, it means the start circuit isn’t

functioning.

No Power

•

If neither the solution solenoid nor brush

motor are functioning, proceed to the

Scrub

System (17E) described on page 44

.

•

If the solution solenoid is functioning, then the

24-volt power supply and scrub control relay

coil can be eliminated as the cause. However,

a failed contact or loose wire could still be the

cause.

•

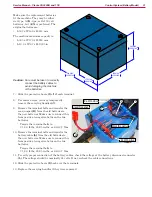

The scrub control relay has 3-pair of

contacts, but only 2-pair are being used. To

verify that the brush motor contacts have

not failed, move the wires for the brush

motor to the unused contact pair. This

pair can be easily identified, because one

of them will connect to the adjacent brush

motor starter.

•

If the brush motor functions after relocating the wires to the unused contacts, then the relay should be

replaced. The relay has severe internal damage and should not be used.

Low Speed, lack of Power, or Overheating

These symptoms and conditions are related to a failed start circuit. If not diagnosed quickly, many of these

conditions can cause permanent damage to the motor. While making observations, it is important to not run

the motor for more than a second or two, and to allow the motor windings to cool down between observations.

Caution!

The motor start and run capacitors can hold a significant electrical charge long after power

has been disconnected. Take care when handling any wires leading to the capacitors.

•

If the brush motor comes up to speed rapidly, but is very noisy, overheats without load, or trips the circuit

breaker, then it is most likely that the start relay is not disconnecting the start capacitor when it should.

Replace the start relay.

•

This condition can rapidly damage the motor. Do not permit the machine to operate in this condition.

•

The motor will sound very loud and unbalanced (not smooth).

•

If the brush motor turns slowly, hums without turning, or is very slow to reach operating speed without

load, then the most likely cause is a failed start capacitor. Replace the start capacitor (see

page 19

)

•

This condition can rapidly damage the motor. Do not permit the machine to operate in this condition.

•

This is the most common failure mode of a capacitor-start motor.

•

If the brush motor gets up to speed reasonably fast but lacks power or bogs down easily, it is likely that

the run capacitor has failed.

Scrub Switches

(Disconnected)

Wire to

Brush Starter

Unused

Contacts