25

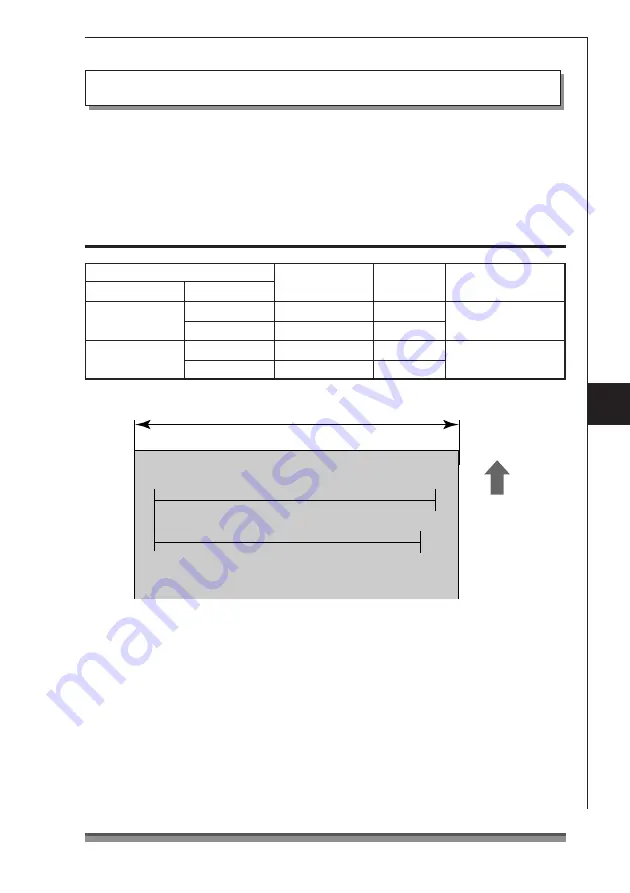

The printing dot line columns are changed as follows by setting the “Paper Width” of the

roll paper used, the “Line Columns,” and the “Font Select” in Soft SW Setting Mode.

For details about setting, see Soft SW Setting Mode (page 35).

When setting Paper Width of 76.2mm

Paper width: 76.2mm

When Line Columns 40/33 are selected: 400 dots

When Line Columns 42/35 are selected: 386 dots

Paper feed

direction

Setting the Paper Width and Printing Line Column Number

Pr

eparing the Print

er

Soft SW Setting Mode

Space between

characters

Printing line

columns

Full columns

Line Columns

Font Select

40/33

9Ω9 dots

3 dots

33 columns

400 dots

7Ω9 dots

3 dots

40 columns

42/35

9Ω9 dots

2 dots

35 columns

386 dots

7Ω9 dots

2 dots

42 columns

Summary of Contents for CD-S500 series

Page 1: ...CD S500 Series CD S500a User s Manual DOT MATRIX PRINTER ...

Page 51: ......