Step 3

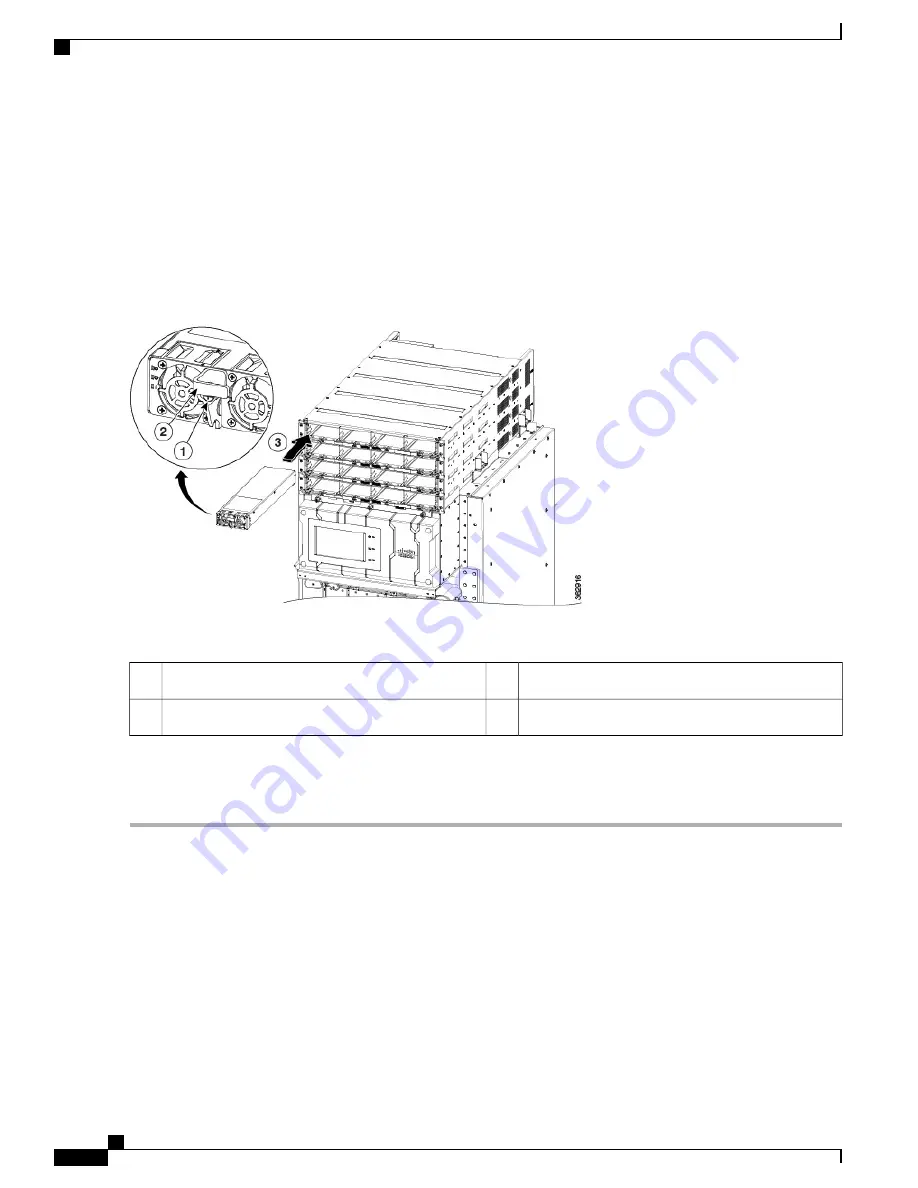

Rotate the ejector lever upwards to seat the PM into the power tray.

Step 4

Tighten the ejector lever screw to a nominal installation torque of 5.5 in-lb (0.62 N-m). Do not exceed a maximum

installation torque of 10 in-lb (1.13 N-m).

Figure 33: Installing a Power Module into a Power Tray

—

DC Power Tray Shown

Ejector lever screw

3

Power module

1

Ejector lever

2

Step 5

Fill the power tray, in PM ascending order, to the required configuration.

Step 6

If necessary, repeat these steps for the remaining power trays.

About the Power Module Status Indicators

The input-power-present LED on the AC and DC power modules provide a visual indication that voltage is

present across the input terminal connection.

•

For DC power modules, the DC input LED lights up when the input voltage reaches within the acceptable

range.

•

For AC power modules, the AC Input LED lights up when the input voltage reaches within the acceptable

range.

Cisco Network Convergence System 6000 Fabric Card Chassis Hardware Installation Guide

50

Installing the Power Components

About the Power Module Status Indicators