MASTER CYLINDER FLUID RESERVOIR FILL TUBE

The master cylinder fluid reservoir filler neck is

removable from the master cylinder fluid reservoir.

The filler neck if required, can be replaced as a sep-

arate component of the fluid reservoir.

The filler neck is removed and installed using the

following procedure.

REMOVE

(1) Check brake fluid level in master cylinder fluid

reservoir to be sure brake fluid is not in the filler

neck. If brake fluid is in filler neck, lower fluid level

before removing filler neck from fluid reservoir

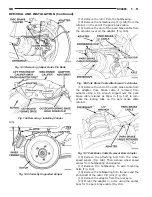

(2) Grasp filler neck at cap end (Fig. 177) and

push straight down. This will cause the filler neck to

pop out of the fluid reservoir.

INSTALL

(1) Wet the O-ring on the reservoir end of the filler

neck with fresh clean brake fluid.

(2) Position the filler neck in the opening on the

fluid reservoir. Ensure tab on filler neck (Fig. 177) is

in the groove on the front of the fluid reservoir.

(3) Push down while slightly rocking filler neck

until filler neck snaps into the fluid reservoir open-

ing.

(4) Install cap on filler neck.

(5) Check and/or add brake fluid in reservoir to

ensure it is at the correct level.

MASTER CYLINDER BRAKE FLUID LEVEL SWITCH

The master cylinder or brake fluid reservoir does

not have to be removed from the vehicle for replace-

ment of the brake fluid level sensor.

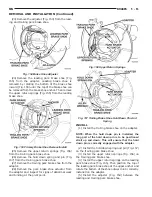

(1) Remove wiring harness connector from brake

fluid reservoir level sensor (Fig. 178).

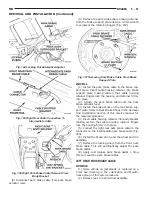

(2) Using fingers, compress the retaining tabs on

the end of brake fluid level switch (Fig. 179).

(3) With retaining tabs compressed, (Fig. 179)

grasp opposite end of brake fluid level switch and

pull it out of master cylinder brake fluid reservoir.

(4) Insert the replacement brake fluid level sensor

into brake fluid reservoir. Be sure sensor is pushed

in until retaining tabs (Fig. 179) lock it to the brake

fluid reservoir.

(5) Connect the vehicle wiring harness connector

to the brake fluid level sensor (Fig. 178).

FRONT DISC BRAKE CALIPER

CLEANING AND INSPECTION

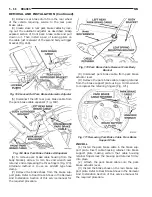

Check for brake fluid leaks in and around dust

boot area and inboard brake pad, and for any rup-

tures, brittleness or damage to the piston dust boot.

If the dust boot is damaged, or a fluid leak is visible,

disassemble caliper assembly and install a new pis-

ton seal and dust boot, and piston if scored. Refer to

Caliper Disassembly And Re-Assembly Procedures in

Disc Brake Caliper Service in this section of the ser-

vice manual.

Fig. 177 Master Cylinder Fluid Reservoir Filler Neck

Fig. 178 Fluid Level Sensor Electrical Connection

Fig. 179 Master Cylinder Brake Fluid Level Sensor

NS

BRAKES

5 - 71

DISASSEMBLY AND ASSEMBLY (Continued)

Summary of Contents for 1998 Voyager

Page 8: ...FASTENER IDENTIFICATION NS INTRODUCTION 5 GENERAL INFORMATION Continued ...

Page 9: ...FASTENER STRENGTH 6 INTRODUCTION NS GENERAL INFORMATION Continued ...

Page 11: ...METRIC CONVERSION 8 INTRODUCTION NS GENERAL INFORMATION Continued ...

Page 12: ...TORQUE SPECIFICATIONS NS INTRODUCTION 9 GENERAL INFORMATION Continued ...

Page 16: ......

Page 26: ......

Page 93: ...RED BRAKE WARNING LAMP FUNCTION NS BRAKES 5 11 DIAGNOSIS AND TESTING Continued ...

Page 94: ...POWER BRAKE SYSTEM DIAGNOSTICS 5 12 BRAKES NS DIAGNOSIS AND TESTING Continued ...

Page 95: ...VEHICLE ROAD TEST BRAKE NOISE NS BRAKES 5 13 DIAGNOSIS AND TESTING Continued ...

Page 222: ...COOLING SYSTEM DIAGNOSIS 7 8 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 223: ...NS COOLING SYSTEM 7 9 DIAGNOSIS AND TESTING Continued ...

Page 224: ...7 10 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 225: ...NS COOLING SYSTEM 7 11 DIAGNOSIS AND TESTING Continued ...

Page 226: ...7 12 COOLING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 280: ......

Page 286: ......

Page 289: ...CHARGING SYSTEM SCHEMATIC TYPICAL NS CHARGING SYSTEM 8C 3 DIAGNOSIS AND TESTING Continued ...

Page 291: ...CHARGING SYSTEM TEST NS CHARGING SYSTEM 8C 5 DIAGNOSIS AND TESTING Continued ...

Page 292: ...OVERCHARGE TEST 8C 6 CHARGING SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 294: ...VOLTAGE DROP TEST 8C 8 CHARGING SYSTEM NS ...

Page 298: ......

Page 372: ......

Page 377: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 5 DIAGNOSIS AND TESTING Continued ...

Page 378: ...8E 6 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 379: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 7 DIAGNOSIS AND TESTING Continued ...

Page 380: ...8E 8 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 381: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 9 DIAGNOSIS AND TESTING Continued ...

Page 382: ...8E 10 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 383: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 11 DIAGNOSIS AND TESTING Continued ...

Page 384: ...8E 12 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 385: ...NS GS INSTRUMENT PANEL AND SYSTEMS 8E 13 DIAGNOSIS AND TESTING Continued ...

Page 386: ...8E 14 INSTRUMENT PANEL AND SYSTEMS NS GS DIAGNOSIS AND TESTING Continued ...

Page 402: ......

Page 428: ......

Page 440: ......

Page 478: ......

Page 496: ......

Page 504: ......

Page 508: ......

Page 524: ......

Page 542: ......

Page 546: ......

Page 550: ......

Page 559: ...SPECIAL TOOLS SPECIAL TOOL Degausser 6029 NS OVERHEAD CONSOLE 8V 9 ...

Page 560: ......

Page 562: ......

Page 564: ...8W 01 2 8W 01 GENERAL INFORMATION NS GS DESCRIPTION AND OPERATION Continued ...

Page 565: ...NS GS 8W 01 GENERAL INFORMATION 8W 01 3 DESCRIPTION AND OPERATION Continued ...

Page 580: ......

Page 616: ......

Page 660: ......

Page 664: ......

Page 704: ......

Page 718: ......

Page 728: ......

Page 740: ......

Page 744: ......

Page 758: ......

Page 768: ......

Page 784: ......

Page 792: ......

Page 796: ......

Page 800: ......

Page 814: ......

Page 822: ......

Page 826: ......

Page 832: ......

Page 836: ......

Page 840: ......

Page 876: ......

Page 1024: ......

Page 1220: ...Fig 3 Lubrication Lines 9 42 ENGINE NS GS DESCRIPTION AND OPERATION Continued ...

Page 1224: ...ENGINE DIAGNOSIS MECHANICAL CONT 9 46 ENGINE NS GS DIAGNOSIS AND TESTING Continued ...

Page 1286: ...Fig 5 Front Crossmember Dimensions 13 6 FRAME AND BUMPERS NS SPECIFICATIONS Continued ...

Page 1287: ...Fig 6 Engine Compartment Top View NS FRAME AND BUMPERS 13 7 SPECIFICATIONS Continued ...

Page 1289: ...Fig 8 Full Vehicle Bottom View NS FRAME AND BUMPERS 13 9 SPECIFICATIONS Continued ...

Page 1291: ...Fig 11 Body Side Openings NS FRAME AND BUMPERS 13 11 SPECIFICATIONS Continued ...

Page 1292: ......

Page 1302: ...FUEL PRESSURE BELOW SPECIFICATIONS 14 8 FUEL SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 1304: ...FUEL INJECTOR DIAGNOSIS 14 10 FUEL SYSTEM NS DIAGNOSIS AND TESTING Continued ...

Page 1368: ......

Page 1426: ......

Page 1472: ......

Page 1479: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 5 DIAGNOSIS AND TESTING Continued ...

Page 1480: ...Diagnosis Guide 21 6 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1481: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 7 DIAGNOSIS AND TESTING Continued ...

Page 1482: ...Diagnosis Guide 21 8 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1483: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 9 DIAGNOSIS AND TESTING Continued ...

Page 1484: ...Diagnosis Guide 21 10 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1485: ...Diagnosis Guide NS TRANSAXLE AND POWER TRANSFER UNIT 21 11 DIAGNOSIS AND TESTING Continued ...

Page 1486: ...Diagnosis Guide 21 12 TRANSAXLE AND POWER TRANSFER UNIT NS DIAGNOSIS AND TESTING Continued ...

Page 1656: ......

Page 1723: ...LEAD CORRECTION CHART NS TIRES AND WHEELS 22 5 DIAGNOSIS AND TESTING Continued ...

Page 1726: ...SPECIFICATIONS TIRE SPECIFICATIONS 22 8 TIRES AND WHEELS NS ...

Page 1866: ......

Page 1904: ......

Page 1928: ......