E N G I N E E L E C T R IC A L

6 Y - 2 3

Check energizer. Test is not valid unless energizer is

good and fully charged.

Inspect the wiring for defects. Check all connections

for tightness and cleanliness, including the slip

connectors at the generator and firewall, and the

cable clamps and battery posts.

With ignition switch “on” connect a voltmeter from

generator “BAT” terminal to ground, generator No.

1 terminal to ground and generator No. 2 terminal

to ground. A zero reading indicates an open

between voltmeter connection and Energizer.

NOTE: An open No. 2 lead circuit on

generators will cause uncontrolled voltage,

Energizer overcharge and possible damage to

Energizer and accessories. Generators sup

plied for current applications have a built-in

feature which avoids overcharge and acces

sory damage by preventing the generator

from turning on if there is an open in the

wiring harness connected to the No. 2

generator terminal. Opens in the wiring

harness connected between the No. 2

generator terminal and Energizer may be

between the terminals, at the crimp between

the harness wire and terminal, or in the wire.

If previous Steps 1 through 5 check satisfactorily,

check Delcotron generator as follows:

a. Disconnect Battery ground cable.

b. Connect an ammeter in the circuit at the “BAT”

terminal of the generator.

c. Reconnect Battery ground cable.

d. Turn on radio, windshield wipers, lights high

beam and blower motor high speed. Connect a

carbon pile across the Battery.

e. Operate engine at moderate speed as required,

and adjust carbon pile as required, to obtain

maximum current output.

f. If ampere output is within 10 percent of rated

output as stamped on generator frame, genera

tor is not defective; recheck Steps 1 through 5.

g. If ampere output is not within 10 percent of

rated output, ground the field winding by

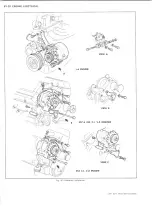

inserting a screwdriver into the test hole (Fig.

1C).

CAUTION:

Tab is within 3/4 inch of casting

surface. Do not force screwdriver deeper than

one inch into end frame.

h. Operate engine at moderate speed as required,

and adjust carbon pile as required to obtain

maximum current output.

i. If output is within 10 percent of rated output,

replace regulator as covered in the Overhaul Manual

and check field winding.

j. If output is not within 10 percent of rated

output, check the field winding, diode trio,

rectifier bridge, and stator as covered in the

Chassis Overhaul Manual.

k. Remove ammeter from generator and turn

accessories off.

OVERCHARGED ENERGIZER

CONDITION CHECK

1. Determine Energizer condition. Test is not valid if

Energizer is not good and fully charged.

2. Connect a voltmeter from generator No. 2 terminal

to ground. If reading is zero, No. 2 lead circuit is

open.

3. If Energizer and No. 2 lead circuit check good, but

an obvious overcharge condition exists as evidenced

by excessive Energizer water usage, proceed as

follows:

a. Separate end frames as covered in Delcotron

“Disassembly” section in the Overhaul Manual.

Check field winding for shorts. If shorted replace

rotor and regulator.

b. Connect ohmmeter using lowest range scale

from brush lead clip to end frame as shown in

Step 1, Figure

8

C, then reverse lead connections.

c. If both readings are zero, either the brush lead

clip is grounded, or regulator is defective.

d. A grounded brush lead clip can result from

omission of insulating washer (Fig.

8

C),

omission of insulating sleeve over screw, or

damaged insulating sleeve. Remove screw to

inspect sleeve. If satisfactory, replace regulator

as covered in the Overhaul Manual.

GENERATOR OUTPUT TEST

To check the generator in a test stand, proceed as

follows:

1. Make connections as shown in Figure 9C, except

leave the carbon pile disconnected. Use a fully

charged Energizer or battery, and a 10 ohm resistor

rated at six watts or more between the generator

No. 1 terminal and the Energizer.

2. Slowly increase the generator speed and observe the

voltage.

3. If the voltage is uncontrolled with speed and

increases above 16 volts, check for a grounded

brush lead clip as covered under heading of

“OVERCHARGED ENERGIZER”, Step 3. If not

grounded, replace the regulator.

NOTE: The Energizer must be fully charged

when making this check.

4. Connect the carbon pile as shown.

5. Operate the generator at moderate speed as

required and adjust the carbon pile as required to

obtain maximum current output.

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......