1A-24 HEATER A N D AIR C O N D I T IO N I N G

ra3S2Qp3pj|3

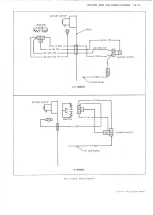

Fig. 3 1 - R e u s in g R e fr ig e r a n t

That is where we find the biggest difference between the

old icebox and the modern refrigerator. We used to put

in new ice to replace that lost by melting. Now we use

the same refrigerant over and over again.

We can change a vapor back into a liquid by chilling it,

or do the same thing with pressure. When we condense a

vapor we will find that the heat removed just exactly

equals the amount of heat that was necessary to make

the substance vaporize in the first place.

This is called the latent heat of vaporization - the heat

that apparently disappeared when a liquid boiled into a

vapor—again reappears - when that same vapor reverts

back into a liquid. It is just like putting air into a balloon

to expand it and then letting the same amount of air out

again to return the balloon to its original condition.

We know that any substance will condense at the same

temperature at which it boiled. This temperature point is

a clear-cut division like a fence. On one side, a substance

is a liquid. Immediately on the other side it is a vapor.

Whichever way a substance would go, from hot to cold

or cold to hot, it will change its character the moment it

crosses over the fence.

Water will boil at 212° under normal conditions.

Naturally, we expect steam to condense at the same

temperature. But whenever we put pressure on steam, it

doesn’t. It will condense at some temperature higher

than 212°. The greater the pressure, the higher the

boiling point and the temperature at which a vapor will

condense. This is the reason why pressure cookers cook

food faster, since the pressure on the water permits it to

boil out at a higher temperature.

We know that R-12

boils

at 21.7° below zero. A

thermometer will show us that the rising vapors, even

though they have soaked up lots of heat, are only slightly

warmer. But the vapors must be made warmer than the

room air if we expect heat to flow out of them. The

condensing point temperature must be above that of

room air or else the vapors won’t condense.

This is where pressure helps, with pressure, we can

compress the vapor, thereby concentrating the heat it

contains. When we concentrate heat in a vapor that way,

we increase the intensity of the heat or, we increase the

temperature, because temperature is merely a measure

ment of heat intensity (fig. 32).

Pressure in Refrigeration

Because we must use pressures and gauges in air

conditioning service, the following points are mentioned

so that we will all be talking about the same thing when

we speak of pressures.

All pressure, regardless of how it is produced, is

measured in pounds per square inch (psi).

Atmospheric Pressure is pressure exerted in every

direction by the weight of the atmosphere. At sea level

atmospheric pressure is 14.7 psi. At higher altitudes air

has less weight (lower psi).

Any pressure less than atmospheric (14.7) is known as a

partial vacuum or commonly called a vacuum. A perfect

vacuum or region of no pressure has never been

mechanically produced.

Gauge pressure is used in refrigeration work. Gauges are

calibrated in pounds (psi) of pressure and inches of

Mercury for vacuum. At sea level, "O " lbs. gauge

pressure is equivalent to 14.7 lbs. atmospheric pressure.

Pressure greater than atmospheric is measured in pounds

(psi) and pressure below atmospheric is measured in

inches of vacuum. The "O" on the gauge will always

correspond to the surrounding atmospheric pressure,

regardless of the elevation where the gauge is being

used.

Pressure-Temperature Relationships of R-12

A definite pressure and temperature relationship exists in

the case of liquid refrigerants and their saturated vapors.

Increasing the temperature of a substance causes it to

expand. When the substance is confined in a closed

container, the increase in temperature will be accompa

nied by an increase in pressure, even though no

mechanical device was used. For every temperature,

there will be a corresponsing pressure within the

container of refrigerant. A table of the temperature-

pressure relationship of R-12 is presented below.

Pressures are indicated in gauge pressure, either positive

pressure (above atmospheric) in pounds or negative

pressure (below atmospheric) in inches of vacuum.

Thus if a gauge is attached to a container of R-12 and

the room temperature is 70°, the gauge will register

approximately 70 psi pressure; in a 100° room, the

pressure would be 117 psi.

Pressure and Flow

When we use a tire pump to inflate an automobile tire,

we are creating pressure only because we are "pushing"

against the air already entrapped inside the tire. If a tire

has a puncture in it, you could pump all day, and still not

be able to build up any pressure. As fast as you would

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......