79033095 C Rev.

1-7

Introduction

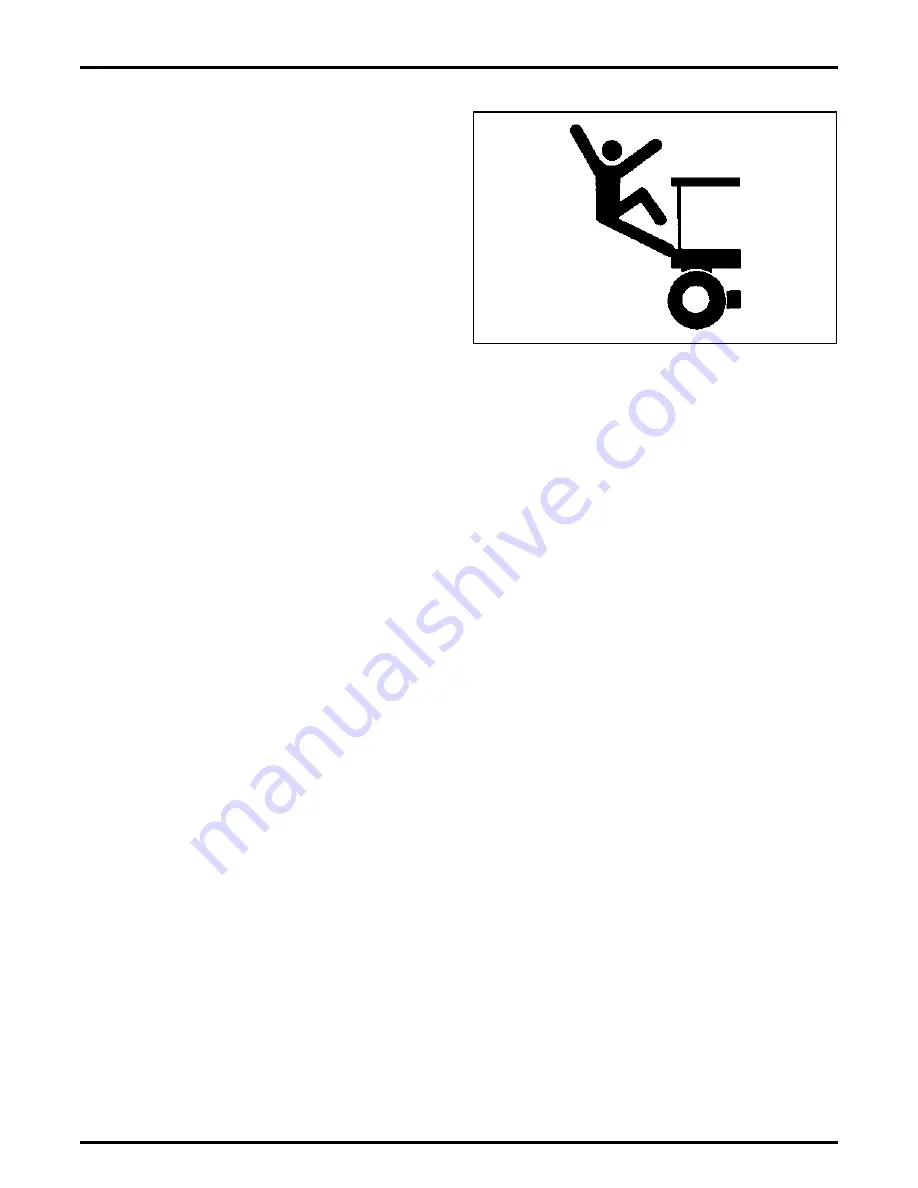

Mounting and Dismounting

FIG. 8:

Mount and dismount machine only where there

are steps and/or hand holds. Face machine whenever

mounting or dismounting.

Maintain three-point contact with steps and hand holds.

Three-point contact is two feet and one hand or one foot

and two hands.

Never mount or dismount a moving machine. Never jump

off machine except in an emergency.

Do not carry tools or supplies when trying to mount or

dismount machine. Use a hand line to pull equipment

onto platform.

Do not use any controls as hand holds when entering or

exiting operator compartment.

IMPORTANT: Make sure steps are not adjusted too

close to hood of machine.

Leave a minimum dimension of 75 mm between inside

hand hold and hood so there is enough room for

operator's hand.

Crushing Prevention and Cutting

Prevention

Stay clear of center articulation joint area of machine

when engine is running. Connect articulation joint stop

whenever servicing this area.

Support equipment properly when performing work under

equipment. Do not depend on hydraulic cylinders to hold

equipment.

m

WARNING: An implement can fall if a

control lever is moved or if a hydraulic line

breaks.

Never jump across starter solenoid terminals to start

machine. Unexpected machine movement could result.

Never attempt adjustments while machine is moving or

while engine is running.

Whenever there are attachment control linkages,

clearance in linkage area changes with movement of

attachment.

Stay clear of all rotating and moving parts. Keep objects

away from moving fan blades. Fan blades will throw and

cut objects.

Wear gloves to handle wire cable and do not use kinked

or frayed wire cable.

Retainer pins can fly when struck, ensure there are no

personnel in area before striking. Wear protective glasses

to protect eyes. When striking objects, chips or other

debris may fly off. Ensure there will be no injury prior to

striking any object.

FIG. 8

N020903008

Find manuals at http://best-manuals.com/search?&s=CHAL-79033095