CCI.Command

– Troubleshooting

84

5.5 Diagnostics

5.5.1

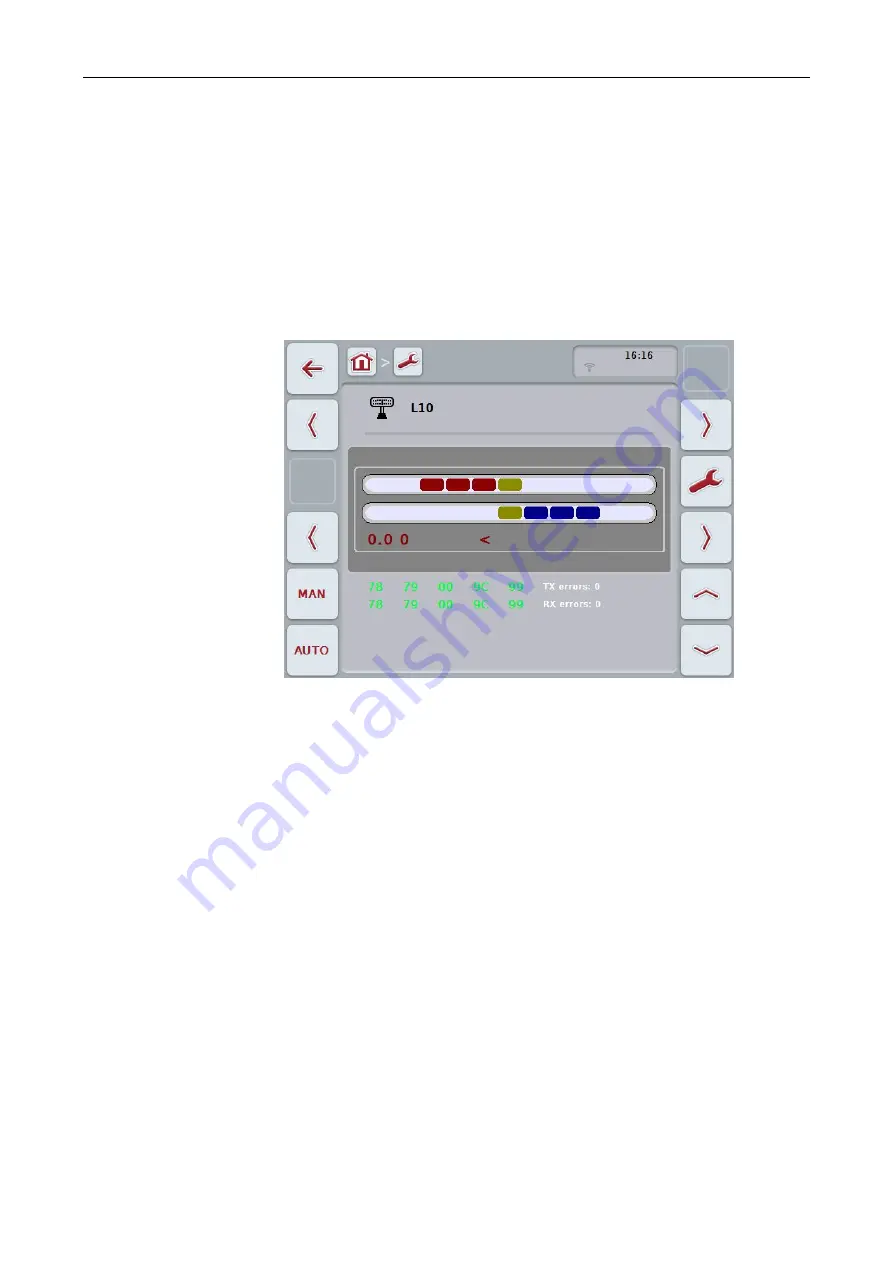

Check external lightbar

To check the external lightbar, proceed as follows:

1. Press the home key to enter the main menu.

2. Press the "Settings" button (F1) in the main menu.

3. Select the tab

Info and Diagnostics

.

4. In the tab

Info and Diagnostics

press the button "L10".

→ The view for the L10 opens:

Pos : 12 /CC-Is obus /*** * Seit enumbruc h * *** @ 8\ mod_1274446340522_0. doc @ 121469 @

Summary of Contents for CCI 100

Page 92: ...CCI Cam Visual implement monitoring Operating instructions Reference CCI Cam v5 ...

Page 118: ...CCI Control Documentation and task management Operating instructions Reference CCI Control v4 ...

Page 224: ...107 10 Notes ...

Page 227: ...110 Edit 38 ...

Page 228: ...CCI TECU Tractor data Operating instructions Reference CCI TECU v6 ...

Page 366: ...CCI GPS GPS settings and tractor geometry Operating instructions Reference CCI GPS v2 ...