Engine - Engine and crankcase

Crankcase - General specification

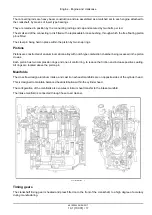

Crank gear

Crankshaft - Bearings

Main journal diameter

79.791 – 79.810 mm

(

3.141 – 3.142 in

)

Main journal undersize

0.254 mm

(

0.010 in

)

0.508 mm

(

0.020 in

)

0.762 mm

(

0.030 in

)

1.016 mm

(

0.040 in

)

Main bearing wall thickness

2.168 – 2.178 mm

(

0.085 – 0.086 in

)

Main bearing under size

0.254 mm

(

0.010 in

)

0.508 mm

(

0.020 in

)

0.762 mm

(

0.030 in

)

1.016 mm

(

0.040 in

)

Main journal clearance in bearings

0.034 – 0.103 mm

(

0.001 – 0.004 in

)

• Maximum wear clearance

0.180 mm

(

0.007 in

)

Crankpin diameter

63.725 – 63.744 mm

(

2.509 – 2.510 in

)

Crankpin undersize

0.254 mm

(

0.010 in

)

0.508 mm

(

0.020 in

)

0.762 mm

(

0.030 in

)

1.016 mm

(

0.040 in

)

Big end bearing wall thickness

1.805 – 1.815 mm

(

0.071 – 0.071 in

)

Big end bearing undersize

0.254 mm

(

0.010 in

)

0.508 mm

(

0.020 in

)

0.762 mm

(

0.030 in

)

1.016 mm

(

0.040 in

)

Crankpin clearance in big end bearing

0.033 – 0.087 mm

(

0.001 – 0.003 in

)

• Maximum wear clearance

0.180 mm

(

0.007 in

)

Crankshaft thrust washer thickness

3.378 – 3.429 mm

(

0.133 – 0.135 in

)

Thrust washer oversize

0.127 mm

(

0.005 in

)

0.254 mm

(

0.508 in

)

0.508 mm

(

0.020 in

)

Width of main bearing housing over thrust washers

31.766 – 31.918 mm

(

1.251 – 1.257 in

)

Length of corresponding main journal

32.000 – 32.100 mm

(

1.260 – 1.264 in

)

Crankshaft end float

0.082 – 0.334 mm

(

0.003 – 0.013 in

)

• Maximum wear clearance

0.400 mm

(

0.016 in

)

Maximum main journal and crankpin ovality or taper after

grinding

0.010 mm

(

0.00039 in

)

Maximum main journal and crankpin ovality or taper due

to wear

0.050 mm

(

0.0019 in

)

Maximum main journal misalignment crankshaft resting

on end journals

0.010 mm

(

0.00039 in

)

Maximum misalignment of crankpins relative to main

journals (in either direction)

0.25 mm

(

0.00098 in

)

Tolerance from outer crankpin edge to crankshaft center

line

±

0.10 mm

(

0.0039 in

)

Maximum crankshaft flange run-out with gauge stylus,

over

108.000 mm

(

4.252 in

) diameter (total gauge

reading)

0.0250 mm

(

0.00098 in

)

Maximum flywheel seat eccentricity relative to main

journals (total gauge reading)

0.0400 mm

(

0.00157 in

)

Side clearance of connecting rod and crankshaft

0.06 – 0.10 mm

(

0.002 – 0.004 in

)

48190544 26/09/2017

10.1 [10.001] / 12

Summary of Contents for 770 EX

Page 5: ...INTRODUCTION 48190544 26 09 2017 1 Find manuals at https best manuals com ...

Page 31: ...SERVICE MANUAL Engine 770EX Magnum 770EX 48190544 26 09 2017 10 ...

Page 33: ...Engine 10 Engine and crankcase 001 770EX Magnum 770EX 48190544 26 09 2017 10 1 10 001 1 ...

Page 51: ...This as a preview PDF file from best manuals com Download full PDF manual at best manuals com ...