7 - MAINTENANCE

Fuel system bleeding

WARNING

Pressurized system!

Only use the bleed screw to bleed air from the fuel system. DO NOT loosen the fuel or injector lines

to bleed air. Injury or damage can occur. Fuel or injector lines are under very high pressure.

Failure to comply could result in death or serious injury.

W0285A

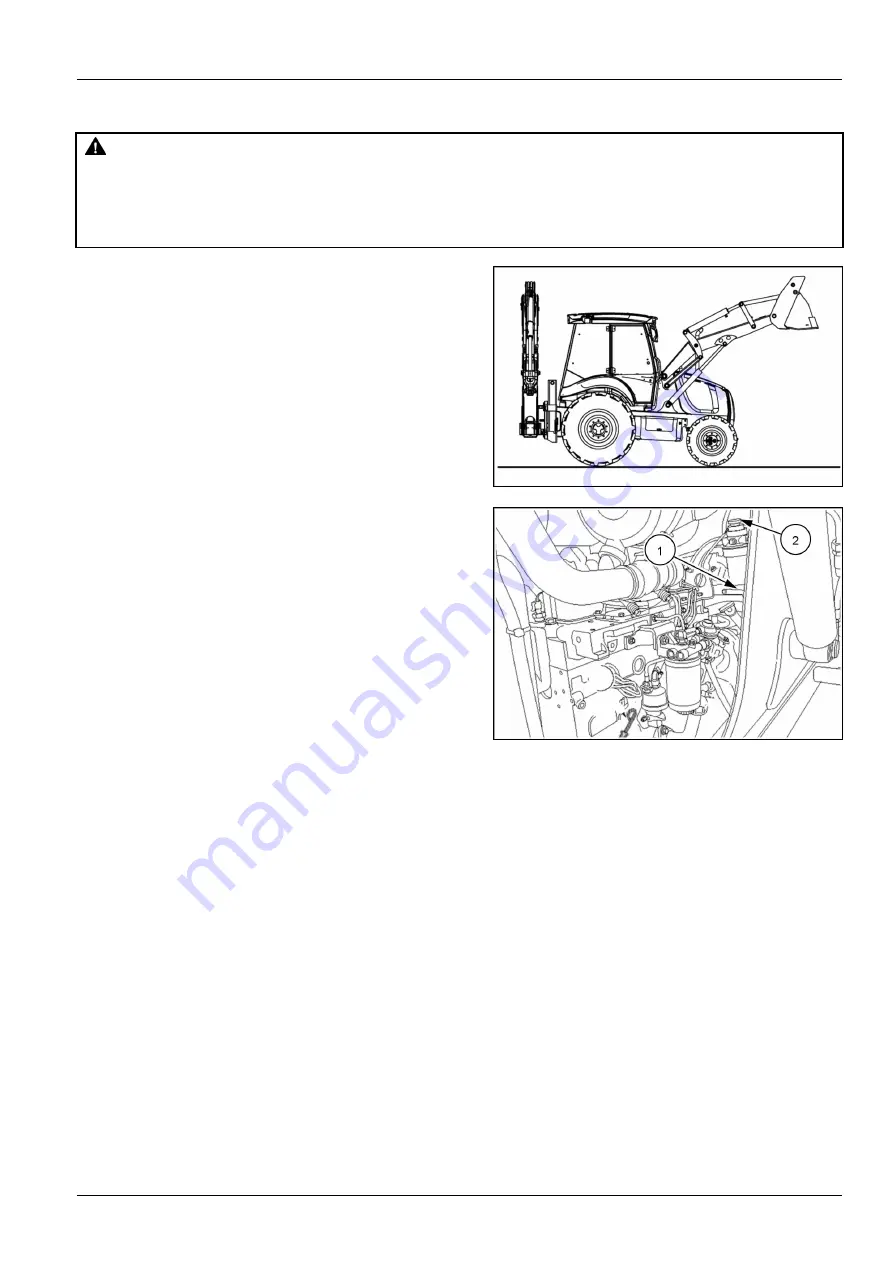

1. From the bottom of the filter, remove the connector

(3)

.

2. Place a container under the prefilter.

3. Open bleed screw

(1)

on prefilter only and activate

hand primer

(2)

until fuel flows freely from the bleed

screw.

4. This generally takes 35-45 pumps to fill the fuel lines

and the prefilter.

5. This can be done in about

30 s

.

6. Tighten bleed screw.

7. Dry with cloth the prefilter.

8. Connect the electric connector under the prefilter.

9. Start the engine. Engine should start within

5 s

.

10. Lower and lock the engine guard.

11. Remove the safety support strut and lower the loader

attachment.

LEEN11T0354AA

1

RAIL15TLB0174AA

2

7-101

Summary of Contents for 580ST

Page 8: ......

Page 24: ...1 GENERAL INFORMATION 1 16 ...

Page 49: ...2 SAFETY INFORMATION Extend telescopic dipper If fitted MOLI12LBB0092AA 24 2 25 ...

Page 101: ...3 CONTROLS AND INSTRUMENTS Setup menu LEIL12TLB00006I 1 3 39 ...

Page 144: ...3 CONTROLS AND INSTRUMENTS 3 82 ...

Page 164: ...4 OPERATING INSTRUCTIONS 4 20 ...

Page 166: ...5 TRANSPORT OPERATIONS RAIL14TLB1181GA 1 5 2 ...

Page 222: ...6 WORKING OPERATIONS 6 44 ...

Page 247: ...7 MAINTENANCE Fuel tank capacity 145 L 38 30 US gal 2WS 124 L 32 76 US gal 4WS 7 25 ...

Page 347: ...7 MAINTENANCE Fuses and relays Powershift cab 2WS MOLI12LBB0491CA 7 7 125 ...

Page 349: ...7 MAINTENANCE Fuses and relays Powershift cab 4WS MOLI12LBB0492CA 8 7 127 ...

Page 390: ...8 TROUBLESHOOTING 8 28 ...

Page 418: ...9 SPECIFICATIONS 4WS LEEN11T0039FA 2 9 28 ...

Page 420: ...9 SPECIFICATIONS 2WS 590ST LEEN11T0041FA 5 4WS 695ST LEEN11T0042FA 6 9 30 ...

Page 433: ......