42

* As the height above sea level increases, there is less oxygen per cubic ft. of air. Therefore, heat input rate should be reduced at higher altitudes.

* As the height above sea level increases, there is less oxygen per cubic ft. of air. Therefore, heat input rate should be reduced at higher altitudes.

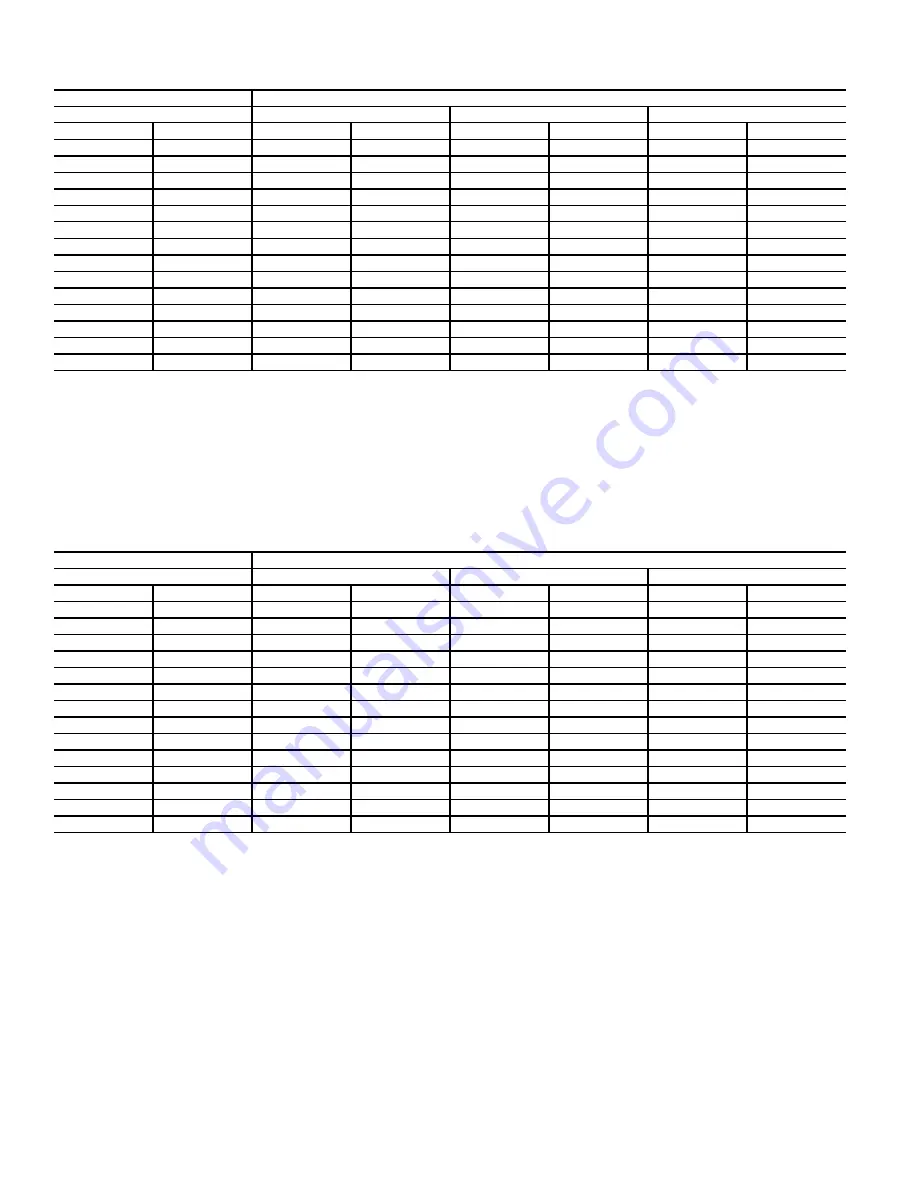

Table 16 — Altitude Compensation* (17-30) for Natural Gas

NATURAL GAS

NOMINAL HEAT INPUT

ELEVATION

220k BTUH

310k BTUH

400k BTUH

Feet

Meters

Orifice Size

Input (btu/hr)

Orifice Size

Input (btu/hr)

Orifice Size

Input (btu/hr)

0-2000

0-610

30

220,000

30

310,000

30

400,000

2000

610

30

202,400

30

285,200

30

368,000

3000

914

31

1

193,600

31

1

272,800

31

1

352,000

4000

1219

31

1

184,800

31

1

260,400

31

1

336,000

5000

1524

31

1

176,000

31

1

248,000

31

1

320,000

6000

1829

31

1

167,200

31

1

235,600

31

1

304,000

7000

2134

32

1

158,400

32

1

223,200

32

1

288,000

8000

2438

32

1

149,600

32

1

210,800

32

1

272,000

9000

2743

34

1

140,800

34

1

198,400

34

1

256,000

10,000

3048

35

2

132,000

35

2

186,000

35

2

240,000

11,000

3353

37

2

123,200

37

2

173,600

37

2

224,000

12,000

3658

37

2

114,400

37

2

161,200

37

2

208,000

13,000

3962

39

2

105,600

39

2

148,800

39

2

192,000

14,000

4267

39

2

96,800

39

2

136,400

39

2

176,000

KIT NO.:

XX

1

= CRNGELEV001A00

XX

2

= CRNGELEV002A00

XX

3

= CRLPELEV005A00

XX

4

= CRLPELEV006A00

XX

5

= CRLPKIT9001A00

Table 17 — Altitude Compensation* (17-30) for Propane Gas

PROPANE GAS

NOMINAL HEAT INPUT

ELEVATION

220k BTUH

310k BTUH

400k BTUH

Feet

Meters

Orifice Size

Input (btu/hr)

Orifice Size

Input (btu/hr)

Orifice Size

Input (btu/hr)

0-2000

0-610

48

5

220,000

48

5

310,000

48

5

400,000

2000

610

49

3

202,400

49

3

285,200

49

3

368,000

3000

914

49

3

193,600

49

3

272,800

49

3

352,000

4000

1219

49

3

184,800

49

3

260,400

49

3

336,000

5000

1524

50

3

176,000

50

3

248,000

50

3

320,000

6000

1829

50

3

167,200

50

3

235,600

50

3

304,000

7000

2134

50

3

158,400

50

3

223,200

50

3

288,000

8000

2438

51

3

149,600

51

3

210,800

51

3

272,000

9000

2743

51

3

140,800

51

3

198,400

51

3

256,000

10,000

3048

52

4

132,000

52

4

186,000

52

4

240,000

11,000

3353

52

4

123,200

52

4

173,600

52

4

224,000

12,000

3658

53

4

114,400

53

4

161,200

53

4

208,000

13,000

3962

53

4

105,600

53

4

148,800

53

4

192,000

14,000

4267

53

4

96,800

53

4

136,400

53

4

176,000

KIT NO.:

XX

1

= CRNGELEV001A00

XX

2

= CRNGELEV002A00

XX

3

= CRLPELEV005A00

XX

4

= CRLPELEV006A00

XX

5

= CRLPKIT9001A00

Summary of Contents for WeatherMaster Puron 48HC D17

Page 18: ...18 COOLING CHARGING CHARTS Fig 22 Cooling Charging Chart 15 Ton ...

Page 19: ...19 Fig 23 Cooling Charging Chart 17 5 Ton ...

Page 20: ...20 Fig 24 Cooling Charging Chart 20 Ton ...

Page 21: ...21 Fig 25 Cooling Charging Chart 25 Ton ...

Page 37: ...37 Fig 48 Unit Control Box IGC Location IGC Board IGC Board Side view Front view ...

Page 40: ...40 Fig 51 Typical IGC Wiring Diagram ...

Page 46: ...46 Fig 57 RTU Open Overlay for Economizer Wiring ...

Page 47: ...47 Fig 58 VFD Overlay for W2770 Controller Wiring ...

Page 84: ...84 Fig B 48HC D17 D28 Control Diagram 208 230 3 60 460 575 3 60 ...

Page 85: ...85 Fig C 48HC D17 D28 Power Diagram 208 230 3 60 ...

Page 86: ...86 Fig D 48HC D17 D28 Power Diagram 460 3 60 ...

Page 87: ...87 Fig E 48HC D17 D28 Power Diagram 575 3 60 ...

Page 88: ...88 Fig F 48HC D17 D28 Control Diagram with Humidi MiZer System ...

Page 89: ...89 Fig G 48HC D17 D28 Power Diagram 208 230 3 60 with Humidi MiZer System ...

Page 90: ...90 Fig H 48HC D17 D28 Power Diagram 460 3 60 with Humidi MiZer System ...

Page 91: ...91 Fig I 48HC D17 D28 Power Diagram 575 3 60 with Humidi MiZer System ...

Page 92: ...92 Fig J PremierLink System Control Wiring Diagram 50HE500891 F ...

Page 93: ...93 Fig K PremierLink System Control Wiring Diagram with Humidi MiZer System ...

Page 94: ...94 Fig L RTU OPEN Wiring Diagram ...

Page 95: ...95 Fig M RTU OPEN Wiring Diagram with Humidi MiZer System ...

Page 97: ......