13

Configure Basic Unit —

The user must be logged on

as Admin to adjust these control configurations.

1. From the HOME menu, select the press the [CONFIG]

softkey to enter the CONFIGURATION menu.

2. From the CONFIGURATION menu, press the [FACTO-

RY] softkey to enter the FACTORY CONFIGURATION

menu.

3. Use arrow keys to scroll around the screen and select the

data field to change. These buttons scroll through the data

fields, as well as up and down the screen.

4. To change a field, move the cursor brackets to the desired

field then press <ENTER>.

5. If the wrong field is entered or you do not want to change

a value, press [CANCEL] to leave the current setting in-

tact.

See Table 4 for a description of the items on the FACTORY

CONFIGURATION menu.

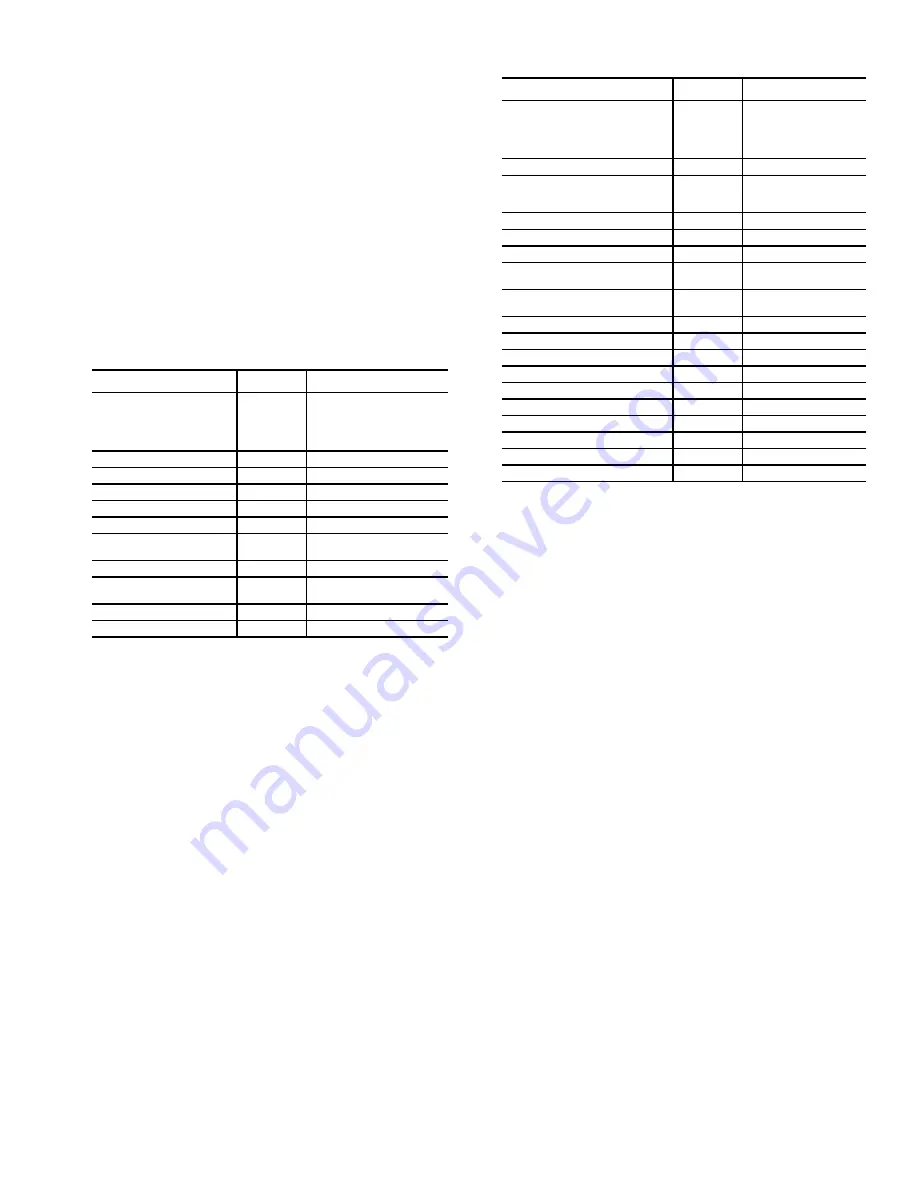

Table 4 — Factory Configuration Menu

*These points are factory set to the appropriate value if affected by a factory-

installed option.

Unit Configuration —

The user must be logged on as

Admin or User to adjust these configuration points.

1. From the HOME menu, select the press the [CONFIG]

softkey to enter the CONFIGURATION menu.

2. From the CONFIGURATION menu, press the [UNIT]

softkey to enter the second CONFIGURATION menu.

3. Use arrow keys to scroll around the screen and select the

data field to change. These buttons scroll through the data

fields, as well as up and down the screen.

4. To change a field, move the cursor brackets to the desired

field then press <ENTER>.

5. If the wrong field is entered, do not change a value, press

[CANCEL] to leave the current setting intact.

See Table 5 for a description of the items on the CONFIGU-

RATION menu.

Table 5 — Configuration Menu

*These points are factory set to the appropriate value if affected by a factory-

installed option.

Unit Status —

The system status can be monitored with-

out logging onto the BACview display by pressing the [Status]

softkey on the HOME menu and using the arrow keys to navi-

gate the screen.

See Table 6 for a description of the items on the on the

UNIT STATUS menu.

Display / Set Runtime Alarms —

It is not necessary

to log onto the BACview display to view the compressor and

fan run time values. It is necessary to log onto BACview to set

runtime limits or clear the accumulated run times.

To view run times, press the [CONFIG] softkey on the

HOME menu, then select the RUNTIME option from the

CONFIGURATION menu. Use the arrow keys to scroll

through the display.

To change runtime alarm values move to the column

marked "Alarm" and press <ENTER> then use the numeric

keys to enter the alarm value and again press <ENTER>. To re-

set the accumulated run time, move to the column marked

"Clear", press <ENTER>, then the [INCR] softkey to select

"Yes", then press <ENTER>. The display will prompt for the

user or admin passwords if the operator is not already logged

on to the display.

Display Alarms and Alarm History —

It is not

necessary to log onto the BACview to display the Current

Alarms or the Alarm History. To view the Alarm information,

press the [ALARM] softkey on the HOME menu.

POINT NAME

DEFAULT

OPTIONS

Occupancy Input Selection

Remote DI

Always Occupied

Local Schedule

BACnet Schedule

BAS On/Off

Remote DI

Airflow Type

Variable*

Constant or Variable

Number of Compressors

4*

2, 3, or 4

Heat Type

None*

None, Hydronic, Electric

Econ Water Flow Type

Constant*

Constant or Variable

Mixed/Return Sensor Type

None*

None, Mixed or Return

Water Econ Freeze Sensor

Type

None*

None, Thermistor, or Switch

Entering Water Temp Sensor

None*

None or Installed

(Condenser) Water Flow

Switch

None*

None or Installed

Modulating Water Valve

None*

None or Installed

Head Pressure Control

None*

None or Enabled

POINT NAME

DEFAULT

OPTIONS

Occupancy Input Selection

Remote DI

Always Occupied

Local Schedule

BACnet Schedule

BAS On/Off

Remote DI

VFD Access Panel Secure

No

No or Yes

Heat Type

None*

None

Hydronic

Electric

Occupied Heating Allowed

Yes

No or Yes

Allow Unoccupied Free Cooling

No

No or Yes

Allow Mechanical Dehumidification

No

No or Yes

Supply Air Reset by EWT (Entering

Water Temperature)

No

No or Yes

Supply Air Reset by SPT (Space

Temperature)

No

No or Yes

Water Econ Flush Type

Timed

Timed or Daily

Air-Side Economizer Installed

None

None or Installed

Outdoor Air Temp Sensor

None

None or Installed

Indoor Air Quality Sensor

None

None or Installed

Indoor Relative Humidity

None

None or Installed

Air-Econ Enthalpy Control

No

No or Yes

Space Static Pressure Control

No

No or Yes

Technician - Area Code

000

3-digit number

Technician - Prefix

000

3-digit number

Technician - Extension

0000

4-digit number