37

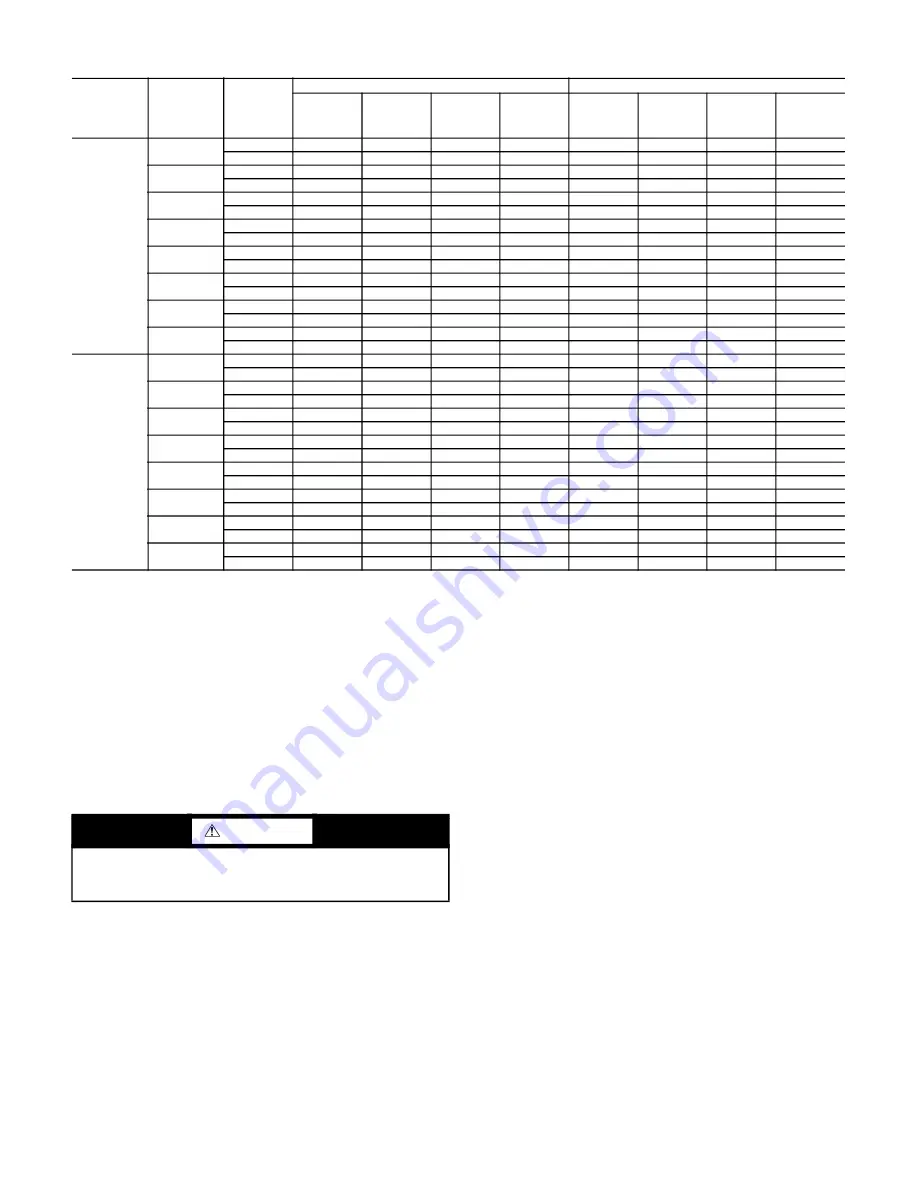

Table 6 —

50HQP,VQP Typical Unit Operating Pressures and Temperatures (cont)

Flow Regulation

Flow regulation can be accomplished by two methods. Most water

control valves have a flow adjustment built into the valve. By

measuring the pressure drop through the unit heat exchanger, the

flow rate can be determined. Adjust the water control valve until

the flow of 1.5 to 2 gpm is achieved. Since the pressure constantly

varies, two pressure gages may be needed in some applications.

An alternative method is to install a flow control device. These

devices are typically an orifice of plastic material designed to al

-

low a specified flow rate that are mounted on the outlet of the wa

-

ter control valve. Occasionally these valves produce a velocity

noise that can be reduced by applying some back pressure. To ac

-

complish this, slightly close the leaving isolation valve of the well

water setup.

Flushing

Once the piping is complete, final purging and loop charging is

needed. A flush cart pump of at least 1.5 hp is needed to achieve

adequate flow velocity in the loop to purge air and dirt particles

from the loop. Flush the loop in both directions with a high vol

-

ume of water at a high velocity. Follow the steps below to properly

flush the loop:

1. Verify power is off.

2. Fill loop with water from hose through flush cart before

using flush cart pump to ensure an even fill. Do not allow

the water level in the flush cart tank to drop below the

pump inlet line to prevent air from filling the line.

3. Maintain a fluid level in the tank above the return tee to

avoid air entering back into the fluid.

4. Shutting off the return valve that connects into the flush

cart reservoir will allow 50 psig surges to help purge air

pockets. This maintains the pump at 50 psig.

5. To purge, keep the pump at 50 psig until maximum pump

-

ing pressure is reached.

6. Open the return valve to send a pressure surge through the

loop to purge any air pockets in the piping system.

7. A noticeable drop in fluid level will be seen in the flush

cart tank. This is the only indication of air in the loop.

NOTE: If air is purged from the system while using a 10 in. PVC

flush tank, only a 1 to 2 in. level drop will be noticed since liquids

are incompressible. If the level drops more than this, flushing

should continue since air is still being compressed in the loop. If

level is less than 1 to 2 in., reverse the flow.

1. Repeat this procedure until all air is purged.

2. Restore power.

Antifreeze may be added before, during or after the flushing pro

-

cess. However, depending on when it is added in the process, it

can be wasted. Refer to the Antifreeze section for more detail.

Loop static pressure will fluctuate with the seasons. Pressures will

be higher in the winter months than during the warmer months.

This fluctuation is normal and should be considered when

charging the system initially. Run the unit in either heating or cool

-

ing for several minutes to condition the loop to a homogenous

temperature.

When complete, perform a final flush and pressurize the loop to a

static pressure of 40 to 50 psig for winter months or 15 to 20 psig

for summer months.

50HQP,

50VQP

UNIT

SIZE

ENTERING

WATER

TEMP

(F)

WATER

FLOW

(GPM/ton)

COOLING

HEATING

Suction

Pressure

(psig)

Discharge

Pressure

(psig)

Water

Temp

Rise

(F)

Air Temp

Drop

(F) DB

Suction

Pressure

(psig)

Discharge

Pressure

(psig)

Water

Temp

Drop

(F)

Air Temp

Rise

(F) DB

300

30

45.0

—

—

—

—

68- 84

256-313

5- 7

19-23

75.0

—

—

—

—

73- 89

261-319

4- 5

20-25

40

45.0

117-143

210-256

15-19

21-26

81- 99

277-339

7- 8

22-26

75.0

114-139

196-239

11-14

22-27

86-105

283-346

5- 6

23-28

50

45.0

120-147

243-297

15-18

20-25

93-114

299-365

8- 9

24-29

75.0

117-143

227-277

11-14

21-26

99-121

305-373

6- 7

25-31

60

45.0

123-150

276-337

14-17

20-24

106-129

321-392

9-11

26-32

75.0

119-146

258-315

11-13

21-25

113-138

327-400

7- 8

28-34

70

45.0

126-154

309-378

14-17

19-24

118-145

342-418

10-12

29-35

75.0

122-149

289-353

10-13

20-25

126-154

349-427

8- 9

30-37

80

45.0

129-157

343-419

13-16

19-23

131-160

364-444

11-14

31-38

75.0

125-153

320-391

10-12

19-24

139-170

371-454

8-10

33-40

90

45.0

132-161

376-459

13-16

18-22

143-175

385-471

12-15

33-41

75.0

128-156

351-429

10-12

19-23

152-186

393-480

9-11

35-43

100

45.0

134-164

409-500

12-15

17-21

—

—

—

—

75.0

131-160

382-467

9-11

18-22

—

—

—

—

360

30

50.0

—

—

—

—

65- 80

282-344

6- 7

14-17

90.0

—

—

—

—

73- 89

294-359

3- 4

15-18

40

50.0

121-148

184-225

17-21

18-22

80- 98

299-365

7- 9

16-20

90.0

117-143

167-204

10-13

19-23

89-108

311-380

4- 5

17-21

50

50.0

123-151

222-271

17-20

17-21

95-116

315-385

9-11

19-23

90.0

119-145

202-247

10-12

18-23

105-128

329-402

5- 7

20-24

60

50.0

125-153

260-318

16-19

17-21

109-133

332-406

11-13

21-26

90.0

120-147

237-289

10-12

18-22

121-148

346-423

6- 8

22-27

70

50.0

127-155

298-365

15-19

17-20

124-151

349-427

12-15

23-28

90.0

122-149

271-331

9-11

18-21

138-168

364-444

7- 9

25-30

80

50.0

129-158

336-411

14-18

16-20

138-169

366-447

14-17

26-31

90.0

124-152

306-374

9-11

17-21

154-188

381-466

8-10

27-33

90

50.0

131-160

374-458

14-17

16-19

153-187

383-468

16-19

28-34

90.0

126-154

340-416

8-10

17-20

170-208

399-487

9-12

29-36

100

50.0

133-162

413-504

13-16

15-19

—

—

—

—

90.0

128-156

375-458

8-10

16-20

—

—

—

—

WARNING

To avoid possible injury or death due to electrical shock, open

the power supply disconnect switch and secure it in an open

position before flushing system.

Summary of Contents for Aquazone 50HQP 072

Page 23: ...23 Fig 20 Single Phase with WSHP Open ...

Page 26: ...26 Fig 23 3 Phase with WSHP Open ...

Page 28: ...28 Fig 25 3 Phase Deluxe D Control Package with 1 Speed VFD and Hot Gas Reheat ...

Page 29: ...29 Fig 26 3 Phase with WSHP Open Hot Gas Reheat Water Economizer and SAVTM ...

Page 31: ...31 Fig 28 WSHP Open W2A Wiring Diagram ...