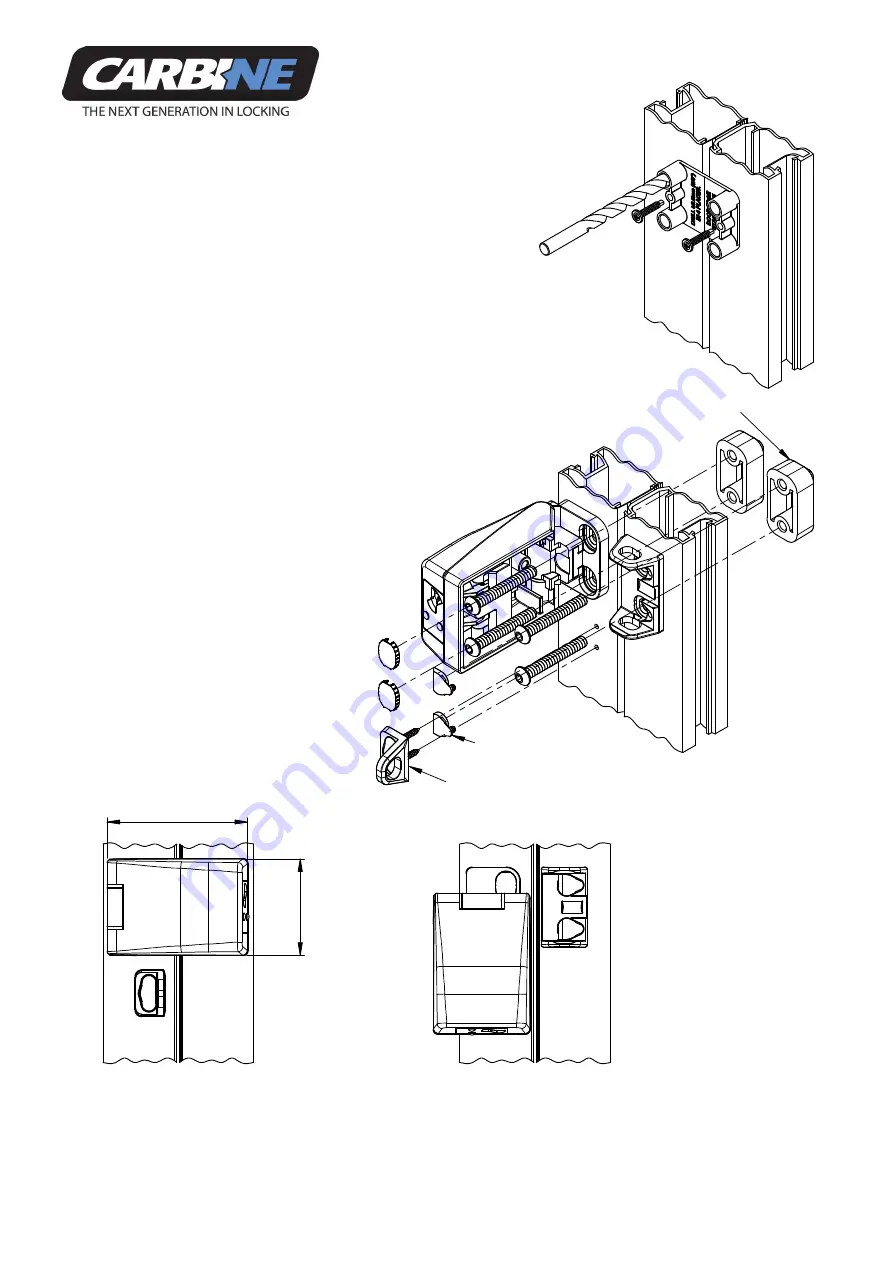

Hasp Clip (for securing the

Hasp in the unlocked position)

Screw Caps x 4

(insert after installation)

Blind Covers x 2

80

m

m

116mm

Locked Position Unlocked Position

Made in China for;

DAVCOR Pty Ltd

14 John Hines Avenue

Minchinbury NSW 2770

AUSTRALIA

www.davcor.com.au

WARRANTY & LIMITATION OF LIABILITY

This DAVCOR product is warranted to be free from defects in materials and workmanship for a period of

one (1) year from the date of the original purchase. This warranty is for replacement of product only

and DAVCOR does not accept any responsibility for any direct or consequential damage caused by this

product or its use. This warranty does not cover damage that from results from faulty installation or

usage, alteration or modification of the product or tarnishing of the finish, including colour damage,

due to weather, salt or chemicals. Should any DAVCOR product not perform satisfactorily to its intended

application then return it to its place of purchase for a replacement.

Page 1/2

!

"#$%&'(()!*"+,-./0!1!2345(%#!6)&3(!

78+9"--"97.8!78+92:/97.8+!

Preparation

Before installing the CARBINE Hasplock ensure that;

1. The maximum gap between the door frames is less than

16mm, as shown on the Drilling Template.

2. There is sufficient clearance for the hasp to swing outwards

and down or up, as shown on the Drilling Template.

Tools required

Electric or cordless drill, Ø9.50mm drill bit for the Hinge and Staple installation,

Ø3.50mm drill bit for the Hasp Clip installation, 5mm Hex Key (supplied) and a

No.2 Phillips screwdriver.

Installation

Use the supplied Drilling Jig by lining up the door frame to the line on the Drilling Jig as

shown. Use the two self drilling and tapping screws to secure the Jig to the frame before

drilling the HaspLock mounting screw holes. Alternatively you can use the Drilling Template

by taping it onto the door frame and centre punching the holes before drilling. If the Hasp

Clip is to be used, centre punch the holes and drill as shown on the Drilling Template.

Fastening

The mounting screws supplied are Buttonhead M8 x 60mm and suit a

45mm frame. For a shorter frame width, cut the screws

back to allow for 10-12mm of protrusion from the

rear of the frame. For deeper frame widths use longer

screws and ensure the same protrusion. For face

mounting, use 14G-16G Pan-Head screws with a

suitable depth that suits the mounting. For correct

operation of the HaspLock, the head thickness

of these screws should not exceed 4mm.

Lock Cylinder

The lock cylinder supplied is a standard 6-pin

key-in-knob style with a C4 keyway.

It can be replaced with another similar style

of cylinder by removing the module from the

Hasp with a 4mm Hex Key (not supplied).

Maintenance

If required, lubricate the Lock Tongues with

graphite powder, DO NOT use grease or oil.