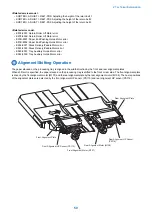

Stacking Operation

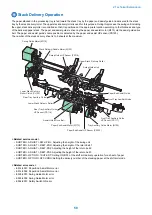

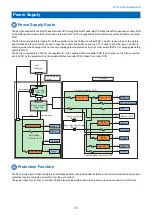

1. The saddle stitcher controller PCB drives the saddle paper end stopper motor (M206) to move the saddle paper end stopper

according to the paper size. Then, it drives the saddle alignment motor (M203) to move the saddle alignment plate to the

paper width +10 mm position.

M203

M206

Rear Saddle

Alignment Plate

Front Saddle

Alignment Plate

Paper Width +10mm

Paper Width+10mm

Saddle Paper End Stopper

Paper

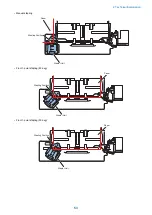

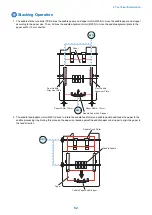

2. The saddle feed/paddle motor (M201) drives to rotate the saddle feed roller and saddle paddle and feeds the paper to the

saddle processing tray. During this process, the paper is pressed against the saddle paper end stopper to align the paper in

the feed direction.

M201

Saddle Paddle

Saddle Feed Roller

Saddle Paper End Stopper

Paper

2. Technical Explanation

62

Summary of Contents for Staple Finisher-AA1

Page 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Page 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Page 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Page 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

Page 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

Page 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Page 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Page 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Page 204: ...4 5 6 7 8 9 7 Installation 196 ...

Page 205: ...10 7 Installation 197 ...

Page 223: ...2 3 2x 7 Installation 215 ...

Page 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...