3-6

Correcting Paper Curl

T

roubleshooting

3

Correcting Paper Curl

If the stacked sheets are curled, correct the curl from the operation panel.

To correct the curl, perform the steps below in order.

1. Set up the curl correction to [AUTO].

2. If the sheets are still curled after step 1 is performed, change the curl correc-

tion amount on the printer.

3. If the sheets are still curled after step 2 is performed, set up the curl correction

to [CONVEX], [CONCAVE], or [OFF].

1

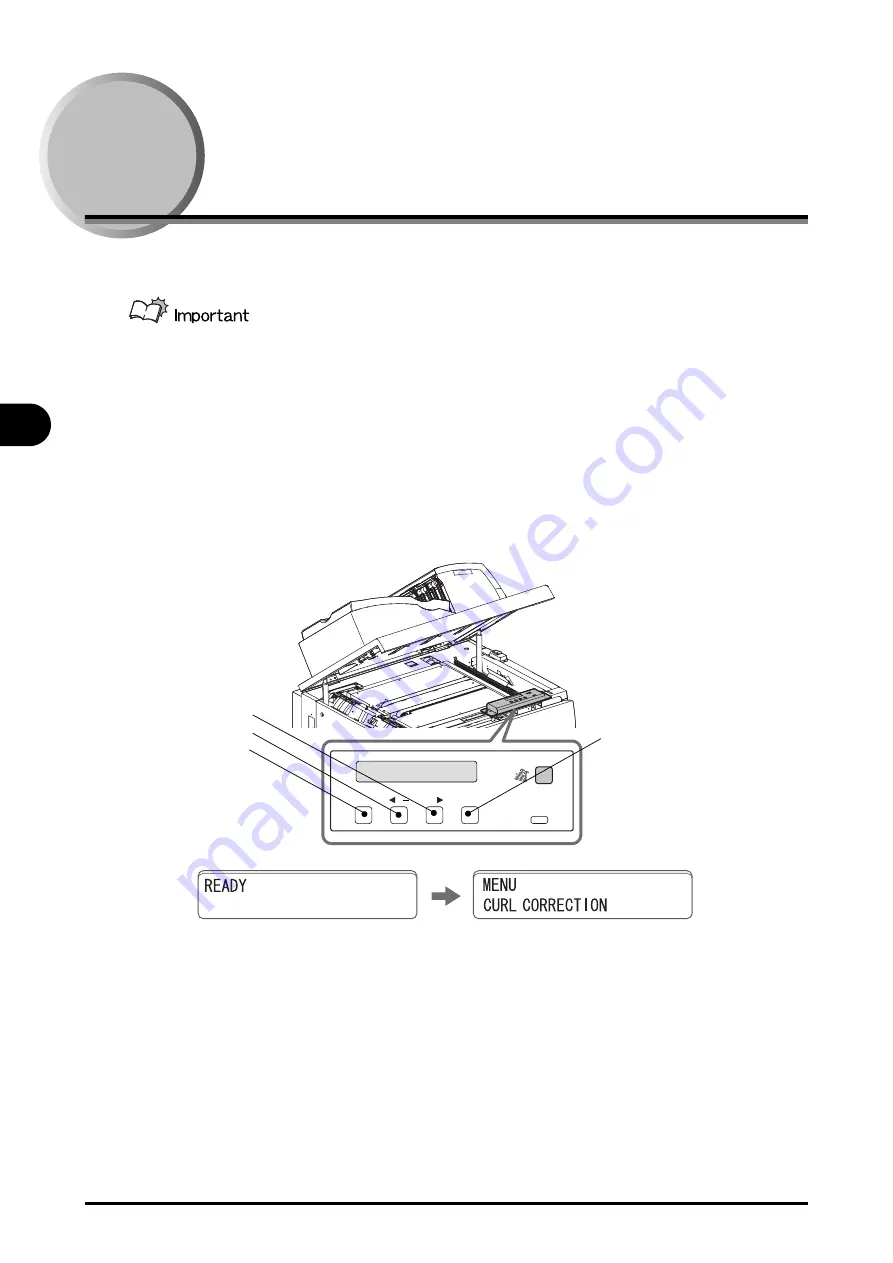

Press the [Menu] on the Standby screen

[MENU CURL CORRECTION] will be displayed on LCD.

2

Press [Enter] on the operation panel.

Error

Enter

Menu

Stack ON/OFF

+ /

/

Enter

+ Key

Menu

- Key

Curl Correction

Summary of Contents for Stacker-C1

Page 1: ...Option_Sta_US Black PANTONE 3288 USRM1 9888 00 CANON INC 2011 C High Capacity Stacker C1 ENG ...

Page 3: ......

Page 22: ...2 1 2 CHAPTER Operating Procedures Stacking Sheets 2 2 Removing Sheets 2 4 ...

Page 36: ...4 1 4 CHAPTER Appendix Specifications 4 2 Index 4 3 ...

Page 39: ...4 4 Index Appendix 4 ...