Chapter 3

3-5

3.3.4 Tray Paper Surface Detection

0020-4695

The machine is equipped with a mechanism to detect the position of the top of the stack deposited in its 2 trays.

The trays are each fitted with a sensor PCB that consists of a light-emitting segment (UN15, UN17) and a light-receiving segment (UN16, UN18).

The light-emitting segment is arranged at the rear of the machine, and is a LED. The light-receiving segment, on the other hand, is found at the front of the machine,

and it consists of 3 photosensors.

When the power is turned on or a jam has been removed, the finisher controller PCB checks the 3 photosensors (light-receiving segment) as soon as the LED (light-

emitting segment) goes on.

As more and more sheets are deposited in the tray, the light reaching the light-receiving segments will be blocked, causing the finisher controller PCB to move

down the tray to keep the top of the stack at a specific level.

When the tray becomes full of paper (i.e., light blocked, not reaching any of the 3 photosensors), the finisher controller PCB switches over to a different tray for

subsequent delivery. If the newly selected tray is full, it will stop the operation of the machine, and will indicate the fact to the host machine.

F-3-8

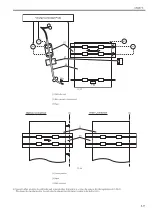

[1] Auxiliary tray solenoid drive signal

SL9: Auxiliary tray solenoid

M23: Tray lift motor

MEMO:

A stack with a folded sheet tends to be higher along its lead edge than its trail edge, blocking the discharge slot when it contains multiple folded sheets. (A subsequent

sheet will likely hit the preceding sheet, causing a jam.)

[1] Paper

[5] Stack delivery roller

[2] Tray A

[6] Tray descent movement (sample)

[3] Tray B

[4] Non-sort delivery roller

UN15: Tray A paper surface sensor (light-emitting)

UN17: Tray B paper surface sensor (light-emitting)

UN16: Tray A paper surface sensor (light-receiving)

UN18: Tray B paper surface sensor (light-receiving)

[1]

[1]

[2]

[3]

[4]

[5]

UN15

UN16

UN16

UN17

UN18

1

2

3

UN16

1

2

3

[1]

[2]

[1]

[2]

[6]

Summary of Contents for Saddle Finisher-AF2

Page 1: ...SERVICE MANUAL Saddle Finisher AF2 MARCH 6 2009...

Page 2: ......

Page 6: ......

Page 12: ...Contents...

Page 13: ...Chapter 1 Specifications...

Page 14: ......

Page 16: ......

Page 22: ......

Page 23: ...Chapter 2 Installation...

Page 24: ......

Page 26: ......

Page 55: ...Chapter 3 Functions...

Page 56: ......

Page 58: ......

Page 104: ...Chapter 3 3 46...

Page 105: ...Chapter 4 Parts Replacement Procedure...

Page 106: ......

Page 110: ......

Page 157: ...Chapter 4 4 47 F 4 213 3 2 1...

Page 158: ......

Page 159: ...Chapter 5 Maintenance...

Page 160: ......

Page 209: ...Chapter 5 5 47 F 5 221 SW382 SW381 SW383 ENTER SW384 SW385 DSP381 1...

Page 218: ......

Page 219: ...Appendix...

Page 220: ......

Page 221: ...General Timing Chart General Circuit Diagram Finisher Sorter DeliveryTray Saddle Finisher AF2...

Page 222: ......

Page 224: ......

Page 225: ...Contents 1 General Circuit Diagram 1 Signal Names 1 General Circuit Diagram 9...

Page 226: ......

Page 243: ......

Page 244: ......