Maintenance Procedure

If print results are blurred, colors are not printed correctly, or print results are unsatisfactory (e.g. misaligned

printed ruled lines), perform the maintenance procedure below.

Important

• Do not rinse or wipe the print head and ink tank. This can cause trouble with the print head and ink

tank.

Note

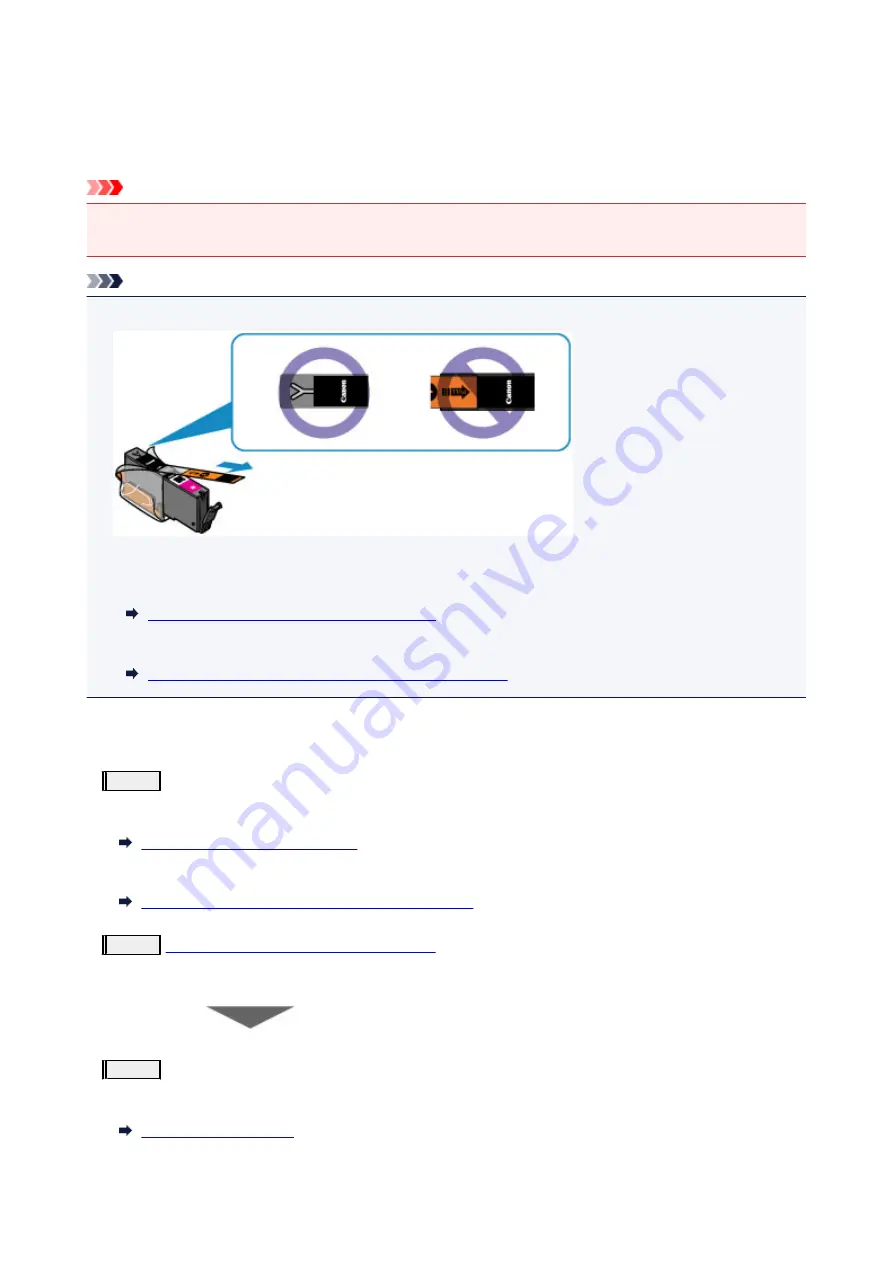

• Make sure that the orange protective tape does not remain on the ink tank.

• Open the operation panel and make sure that the lamp on the ink tank is lit. If the lamp is flashing or off,

take appropriate action.

Checking the Ink Status with the Ink Lamps

• Increasing the print quality in the printer driver settings may improve the print result.

Changing the Print Quality and Correcting Image Data

When the Print Results Are Blurred or Uneven:

Step1

Print the nozzle check pattern.

From the machine

Printing the Nozzle Check Pattern

From the computer

Use Your Computer to Print a Nozzle Check Pattern

Step2

Examine the nozzle check pattern

If there are missing lines or horizontal white streaks in the pattern:

Step3

Clean the print head.

From the machine

From the computer

216

Summary of Contents for PIXMA MG7500 Series

Page 90: ... 8 Display area The display changes based on the menu you select 90 ...

Page 126: ...Safety Guide Safety Precautions Regulatory and Safety Information 126 ...

Page 133: ...Main Components Front View Rear View Inside View Operation Panel 133 ...

Page 150: ...This opens another list of items Drag it in the same manner and tap a setting 150 ...

Page 175: ...175 ...

Page 181: ... D 0 25 inch 6 3 mm 181 ...

Page 204: ...Replacing an Ink Tank Replacing an Ink Tank Checking the Ink Status 204 ...

Page 258: ...Note The effects of the quiet mode may be less depending on the print quality settings 258 ...

Page 275: ...Language selection Changes the language for the messages and menus on the touch screen 275 ...

Page 290: ...Information about Network Connection Useful Information about Network Connection 290 ...

Page 337: ...5 Delete Deletes the selected IP address from the list 337 ...

Page 368: ...Checking the Ink Status with the Ink Lamps 368 ...

Page 375: ...375 ...

Page 403: ...Note Selecting Scaled changes the printable area of the document 403 ...

Page 445: ...Adjusting Brightness Adjusting Intensity Adjusting Contrast 445 ...

Page 542: ...Using the Slide Show Function Printing Photo While Viewing the Slide Show 542 ...

Page 566: ...PictBridge print settings 566 ...

Page 593: ...Scanning Scanning from a Computer Scanning from the Operation Panel of the Machine 593 ...

Page 676: ...Related Topic Scanning Items Larger than the Platen Image Stitch 676 ...

Page 697: ...697 ...

Page 720: ...Related Topic Scanning in Basic Mode 720 ...

Page 773: ...When scanning is completed the scanned image appears in the application 773 ...

Page 848: ...Disc Tray Does Not Feed Properly 848 ...

Page 851: ...Problems with Printing Quality Print Results Not Satisfactory Ink Is Not Ejected 851 ...

Page 958: ...1401 Cause The print head may be damaged Action Contact the service center 958 ...

Page 959: ...1403 Cause The print head may be damaged Action Contact the service center 959 ...

Page 960: ...1405 Cause The print head may be damaged Action Contact the service center 960 ...

Page 968: ...1660 Cause The ink tank is not installed Action Install the ink tank 968 ...

Page 1006: ...5B00 Cause Printer error has occurred Action Contact the service center 1006 ...

Page 1007: ...5B01 Cause Printer error has occurred Action Contact the service center 1007 ...

Page 1008: ...5B10 Cause Printer error has occurred Action Contact the service center 1008 ...

Page 1009: ...5B11 Cause Printer error has occurred Action Contact the service center 1009 ...