Clearing Paper Jams

3-12

T

rou

ble

s

h

oot

ing

3

17

Perform operations in accordance with the instructions that

appear on the printer display.

NOTE

If the display continues to indicate a paper jam clearing procedure, continue to

perform the applicable procedure until the paper jam is cleared.

Clearing a Paper Jam in the Stacker (or Booklet Delivery

Part)

Perform this procedure when a paper jam occurs in the stacker.

CAUTION

Do not do anything other than remove paper. Putting your hand into the

machine may cause an injury.

When the Perfect Binder Continuous Kit is installed, if you need to move

equipment that is installed in front of the booklet delivery part before you clear a

paper jam, then follow the instructions in the manual of the equipment being

moved.

1

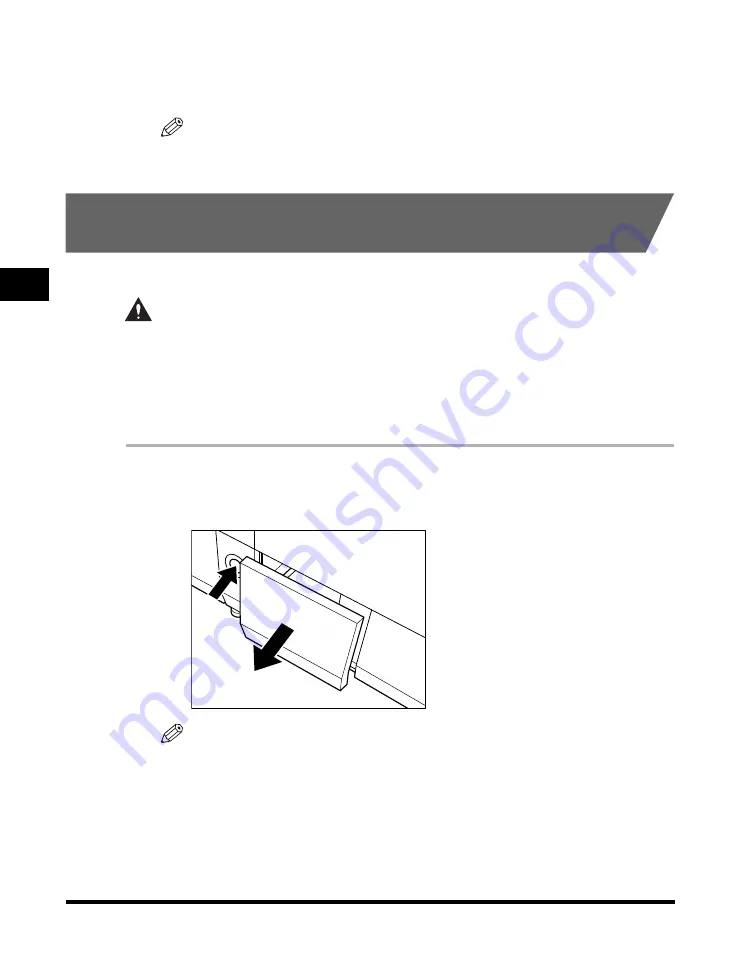

Press the open button and pull out the stacker (E).

Pull the stacker (E) out all the way until it stops.

NOTE

When the Perfect Binder Continuous Kit is installed, if a paper jam occurs, the

booklet delivery part automatically opens a little. Pull the booklet delivery part out

until it stops.