Summary of Contents for LV-S4

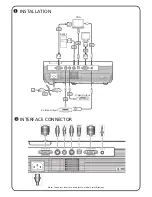

Page 1: ...Multimedia Projector SERVICE MANUAL Original Version FILE NO Model No LV S4 ...

Page 49: ... 49 BA9743AFV DC DC Converter IC371 IC Block Diagrams BA7078AF Sync Detector IC5301 ...

Page 50: ... 50 IC Block Diagrams LM4865 Audio Amplifier IC5003 PW168A Scaler Main CPU IC301 ...

Page 52: ...SERVICE MANUAL LV S4U LV S4E ...