Chapter 13

13-1

13.1

Image Adjustments

13.1.1

Standards for Image

Position

0007-4812

iR2270 / iR2870 / iR3570 / iR4570 / iR3530

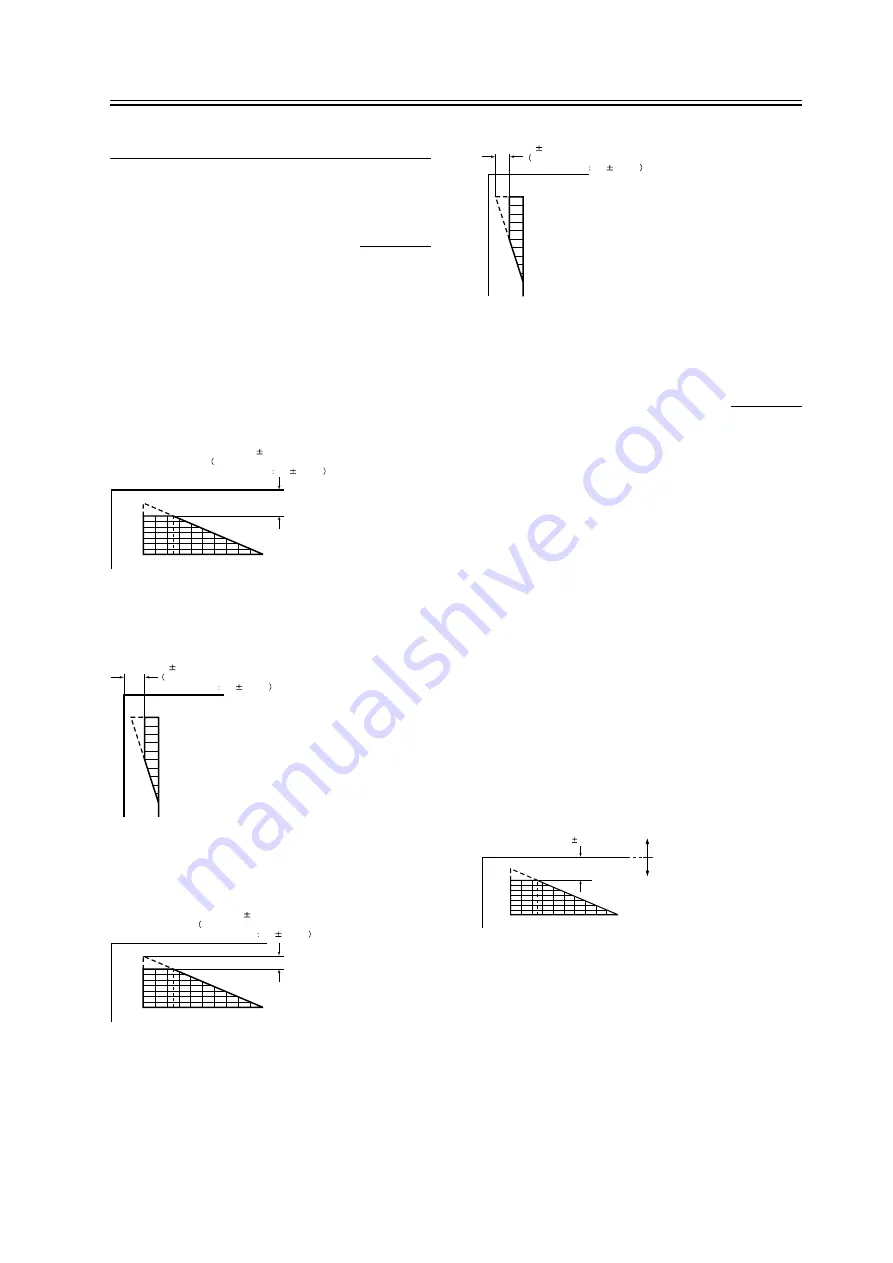

A print made at a magnification of 100% must meet

the following standards for image margin/non-image

width:

- Margin Along the Leading Edge

F-13-1

- Left/Right Image Margin

F-13-2

- Leading Edge Non-Image Width

F-13-3

- Left/Right Non-Image Width

F-13-4

13.1.2

Adjusting the Image

Position

0007-4813

iR2270 / iR2870 / iR3570 / iR4570 / iR3530

Using the source of paper indicated, make 10 prints

each to see if the image margin and the non-image

margin are as indicated:

[1] Cassettes

[2] Manual feed tray

[3] Side paper deck

If not as indicated, adjust the image position as

follows:

1.Adjusting the Leading Edge Image Margin (1st

side)

Adjust the registration in service mode:

COPIER > ADJUST > FEED-ADJ > REGIST

F-13-5

2. Adjusting the Left/Right Image (1st side)

Mechanical Horizontal Registration Adjustment

3. Adjusting the Leading Edge Image Margin (2nd

side)

Adjust the registration in service mode:

2

5

4 6 8 10 12 14 16 18 20

0

2.5

1.5mm

2nd side of double-sided copy

2.5

2.0mm

10

8

6

5

4

2

0

2.5

1.5mm

2nd side of double-sided copy

2.5

2.0mm

2

5

4 6 8 10 12 14 16 18 20

0

2.5

1.5mm

2nd side of double-sided copy

2.5

1.5mm

10

8

6

5

4

2

0

2.5

1.5mm

2nd side of double-sided copy

2.5

1.5mm

Paper

leading edge

Decrease the REGIST setting.

(a decrease of '10' will

increase the margin by 1 mm)

Increase the REGIST setting.

(an increase of '10' will

increase the margin by 1 mm)

2

5

4 6 8 10 12 14 16 18 20

0

1st side of copy : 2.5 1.5mm

Summary of Contents for iR2270 Series

Page 1: ...Jan 31 2005 Service Manual iR4570 3570 2870 2270 Series ...

Page 2: ......

Page 6: ......

Page 29: ...Chapter 1 Introduction ...

Page 30: ......

Page 106: ......

Page 107: ...Chapter 2 Installation ...

Page 108: ......

Page 110: ......

Page 132: ...system setup network Ethernet driver setup auto detect ...

Page 152: ...F 2 94 3 2 3 1 ...

Page 153: ...Chapter 3 Basic Operation ...

Page 154: ......

Page 156: ......

Page 162: ......

Page 163: ...Chapter 4 Main Controller ...

Page 164: ......

Page 204: ......

Page 205: ...Chapter 5 Original Exposure System ...

Page 206: ......

Page 253: ...Chapter 6 Laser Exposure ...

Page 254: ......

Page 256: ......

Page 270: ......

Page 271: ...Chapter 7 Image Formation ...

Page 272: ......

Page 276: ......

Page 289: ...F 7 13 1 2 3 4 ...

Page 348: ......

Page 349: ...Chapter 8 Pickup Feeding System ...

Page 350: ......

Page 356: ......

Page 511: ...Chapter 9 Fixing System ...

Page 512: ......

Page 556: ......

Page 557: ...Chapter 10 External and Controls ...

Page 558: ......

Page 562: ......

Page 632: ......

Page 633: ...Chapter 11 MEAP ...

Page 634: ......

Page 636: ......

Page 641: ...Chapter 12 Maintenance and Inspection ...

Page 642: ......

Page 644: ......

Page 680: ......

Page 681: ...Chapter 13 Standards and Adjustments ...

Page 682: ......

Page 684: ......

Page 703: ...Chapter 14 Correcting Faulty Images ...

Page 704: ......

Page 754: ...T 14 28 Notation Description VR201 for factory use ...

Page 755: ...Chapter 15 Self Diagnosis ...

Page 756: ......

Page 758: ......

Page 841: ...Chapter 16 Service Mode ...

Page 842: ......

Page 844: ...Contents 16 8 1 COPIER 16 102 16 8 1 1 Copier List 16 102 ...

Page 953: ...Chapter 17 Upgrading ...

Page 954: ......

Page 956: ......

Page 962: ...F 17 4 HDD Boot ROM Flash ROM System Software ...

Page 968: ...F 17 12 ...

Page 998: ...Chapter 17 17 42 F 17 56 2 Select the data to download F 17 57 3 Click Start ...

Page 1001: ...Chapter 18 Service Tools ...

Page 1002: ......

Page 1003: ...Contents Contents 18 1 Special Tools 18 1 18 2 Oils and Solvents 18 2 ...

Page 1004: ......

Page 1007: ...Jan 31 2005 ...

Page 1008: ......