Chapter 2

2-20

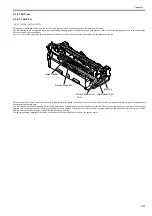

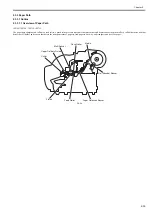

2.3.2.3 Carriage Unit

2.3.2.3.1 Functions of Carriage Unit

0023-1473

iPF765 / iPF760 / iPF750 / iPF755

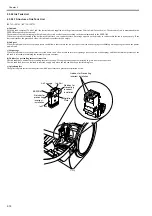

a) Printhead mounting function

The carriage mechanically locks the printhead and transmits the print signals to the printhead via the carriage PCB.

b) Control function

The carriage incorporates a carriage PCB that relays the signal from the main controller, a linear encoder that generates a print timing signal based on the detected

carriage position, and a multi sensor that detects the media width and skewing to adjust the registration and height.

The carriage PCB and main controller PCB are connected with a flexible cable.

c) Carriage drive function

The carriage motor moves the carriage back and forth on the platen via the carriage belt.

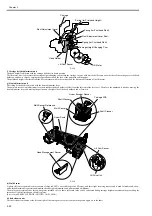

d) Printhead maintenance function

The printer performs the printhead cleaning operation such as printhead wiping and suction at the home position of the carriage.

e) Nozzle check function

The printer detects a non-discharging nozzle using the head management sensor attached to the maintenance jet tray by discharging ink with the carriage stopped

at the maintenance jet tray.

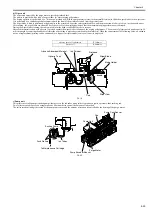

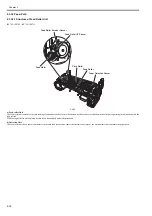

f) Media thickness adjustment function

If the gap between the printhead face and the media increases due to the difference in media thickness, cockling, curling, and so on, more ink mist is generated. In

reverse, if the gap decreases, the head can touch the media surface more frequently.

To maintain the proper gap, the remote lifter is driven to adjust the head height automatically according to the selected media type, media supply method, printing

conditions (borderless/priority print type), environmental conditions (temperature/humidity), and the result of measurement by the multi sensor.

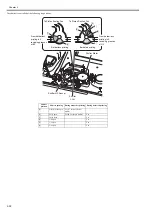

The relationship between media types and head heights (from the platen) is summarized in the table below. Note that the head height is adjusted with priority given

to the media gap measured by the multi sensor.

*1: Roll media, borderless printing, standard mode excert for line document

g) Paper leading edge detection function/paper width detection function/skewing detection function

The leading edge, width, and skewing of the paper fed to the platen is detected by the multi sensor mounted at the lower left of the carriage.

h) Auto printing position adjustment function

The adjustment pattern printed on paper is read by the multi sensor mounted at the lower left of the carriage, thus adjusting the printing timings of each printhead

automatically.

i) Remaining roll media detection function

The amount of the remaining roll paper can be detected using the multi sensor mounted at the lower left of the carriage by printing a barcode at delivery of the roll

media.

j) Internal temperature detection function

The internal temperature around the printhead is detected using the thermistor mounted on the carriage PCB.

Head height (mm)

Media type (Value in parentheses:mm)*1

1.0

(select by the user when using the plain paper)

1.3

Photo paper, Synthetic paper, Backlit film

1.8

Plain paper, Coated paper

2

Heavyweight coated paper

2.2

Premiun matte paper, Special

2.6

Special (at the low humidity or high humidity)

Summary of Contents for iPF750 series

Page 1: ...Jul 25 2012 Service Manual iPF760 750 series ...

Page 2: ......

Page 6: ......

Page 11: ...Chapter 1 PRODUCT DESCRIPTION ...

Page 12: ......

Page 14: ...Contents 1 7 3 5 Self diagnostic Feature 1 71 1 7 3 6 Disposing of the Lithium Battery 1 72 ...

Page 87: ...Chapter 2 TECHNICAL REFERENCE ...

Page 88: ......

Page 99: ...Chapter 2 2 9 ...

Page 145: ...Chapter 3 INSTALLATION ...

Page 146: ......

Page 148: ......

Page 152: ......

Page 153: ...Chapter 4 DISASSEMBLY REASSEMBLY ...

Page 154: ......

Page 156: ......

Page 214: ...Chapter 4 4 58 2 Shaft Cleaner 1 F 4 119 1 ...

Page 215: ...Chapter 4 4 59 3 Upper Cover Hinge Catch 1 Roll Cover Slide Guide 2 F 4 120 2 1 ...

Page 218: ......

Page 219: ...Chapter 5 MAINTENANCE ...

Page 220: ......

Page 222: ......

Page 227: ...Chapter 5 5 5 ...

Page 228: ......

Page 229: ...Chapter 6 TROUBLESHOOTING ...

Page 230: ......

Page 232: ......

Page 250: ......

Page 251: ...Chapter 7 SERVICE MODE ...

Page 252: ......

Page 254: ......

Page 305: ......

Page 306: ......

Page 307: ...Chapter 8 ERROR CODE ...

Page 308: ......

Page 310: ......

Page 327: ...Jul 25 2012 ...

Page 328: ......