• Setting of control temperature(Plain paper2,Cassette)

COPIER > OPTION > IMG-FIX > TMP-TBL7

• Setting of control temperature(OHP)

COPIER > OPTION > IMG-FIX > TMP-TBL8

• Setting of control temperature(Plain paper1,Cassette)

COPIER > OPTION > IMG-FIX > TMP-TBL9

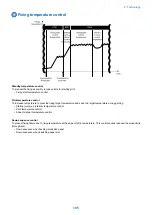

Down sequence control

■ Down sequence when feeding small size paper

Purpose

To prevent temperature rise of non-feeding area in the case of continuous print of small size paper (less than A4 of length in width

direction), fixing offset or deterioration of fixing film.

Starting conditions

1. Normal down sequence

(1) When the detected temperature of sub thermistor (front) or (rear) reaches 255 deg C or higher for 400 msec continuously

during printing

(2) Whenever the thermistor detects 255 deg C or higher for 400 msec continuously, the down sequence is carried out with

the maximum 4 steps.

2. Heavy paper down sequence

(3) When one minute have passed with the heavy paper mode 1/2/3/4, or when the detected temperature of sub thermistor

(front) or (rear) reaches 255 deg C or higher for 400 msec continuously

(4) When the detected temperature of sub thermistor (front) or (rear) reaches 255 deg C or higher for 400 msec continuously

with the heavy paper down sequence, the productivity is compared with the normal down sequence. If the productivity of the

normal down sequence is low, the sequence is shift to the normal down sequence.

Operation

The fixing temperature is reduced by making wider sheet-to-sheet distance to control the temperature at lower than the target

temperature for normal print.

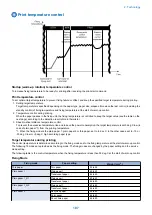

(Unit: sheets)

Down sequence

A4

LTR

B4

LGL

B5

A5

A4R

LTRR

A5R

B5R

EXE-R

Post card

S-Post card

Envelope

Free size

Normal down1

12

20

20

20

18

14

10

12

Normal down2

10

12

12

12

14

10

8

10

Normal down3

8

10

10

10

14

10

8

8

Normal down4

8

8

8

8

14

10

8

8

Heavy paper down

16

8

16

10

16

10

8

8

Completion conditions

(5) When the fixing temperature reaches 175 deg C and lower for 400 msec continuously, the productivity returns to normal.

(6) When the fixing temperature reaches 175 deg C and lower for 400 msec continuously after shifting from the heavy paper

down sequence to the normal down sequence, the sequence is shifted to the heavy paper down sequence.

2. Technology

109

Summary of Contents for imagerunner advance 4551i

Page 19: ...Product Overview 1 Product Lineup 7 Features 13 Specifications 16 Name of Parts 26 ...

Page 155: ...Periodical Service 3 Consumable Parts List 143 Cleaning Check Adjustment Locations 146 ...

Page 392: ...Error Jam Alarm 7 Overview 380 Error Code 383 Jam Code 509 Alarm Code 520 ...

Page 545: ...Service Mode 8 Overview 533 COPIER 549 FEEDER 845 SORTER 851 BOARD 871 ...

Page 892: ...Unpacking 1 2 1200 mm 840 mm 769 mm 1230 mm 2430 mm 3 9 Installation 879 ...

Page 895: ...3 4 NOTE Keep the removed screws for relocating the host machine 2x 5 6 7 9 Installation 882 ...

Page 896: ...8 9 10 1x Installing the Air Filter 1 9 Installation 883 ...

Page 897: ...2 3 Installing the Drum Unit 1 2 3 9 Installation 884 ...

Page 899: ...8 NOTE The screw removed at procedure 4 is used 1x 9 10 11 12 9 Installation 886 ...

Page 923: ...5 6 NOTE Use the screws and Rubber Caps removed in step 1 2x 7 2x 9 Installation 910 ...

Page 935: ...7 1x 8 9 6x 10 2x 9 Installation 922 ...

Page 936: ...11 Installing the NFC Kit 1 2 2x 3 TP M3x4 1x 9 Installation 923 ...

Page 938: ...4 5 1x 6 9 Installation 925 ...

Page 985: ...8 2x 2x TP M4x8 Black When installing the USB Keyboard 1 9 Installation 972 ...

Page 991: ...7 4x 8 1x 1x Lower Cover 9 1x 10 1x 1x 9 Installation 978 ...

Page 992: ...11 1x 1x 12 1x 13 TP M3x12 2x 14 4x TP M3x6 9 Installation 979 ...

Page 997: ...Installation Procedure 1 2 2x 3 2x 4 6x 5 4x 9 Installation 984 ...

Page 998: ...6 7 NOTE Do not close the Wire Saddle 1x 1x 8 9 9 Installation 985 ...

Page 1003: ...2 1x 1x 3 2x 2x 4 9 Installation 990 ...

Page 1012: ...2 1x 1x 3 2x 2x 4 9 Installation 999 ...

Page 1014: ...7 CAUTION The connector must be contacted TP㸹M3x6 3x 1x 8 4x 9 9 Installation 1001 ...

Page 1016: ...13 4x 14 15 Binding M4x16 Binding M3x16 2x M3x16 M4x16 16 Binding M4x6 1x 9 Installation 1003 ...

Page 1023: ...Installation Procedure Preparation 1 4x 2 1x 1x 3 2x 9 Installation 1010 ...

Page 1029: ...4 5 1x 1x 9 Installation 1016 ...

Page 1048: ...3 2x TP M3x8 Black 4 2x TP M3x6 5 9 Installation 1035 ...

Page 1053: ... Installing the Removable HDD Kit 1 2x 2x 2 3 1x 4 9 Installation 1040 ...

Page 1065: ...3 2x TP M3x8 Black 4 2x TP M3x6 5 9 Installation 1052 ...

Page 1071: ... Installing the Removable HDD Kit 1 2x 2x 2 3 1x 4 9 Installation 1058 ...