Entering Characters from the Touch Panel Display

2-24

2

Basic Oper

ations

Entering Characters from the Touch Panel Display

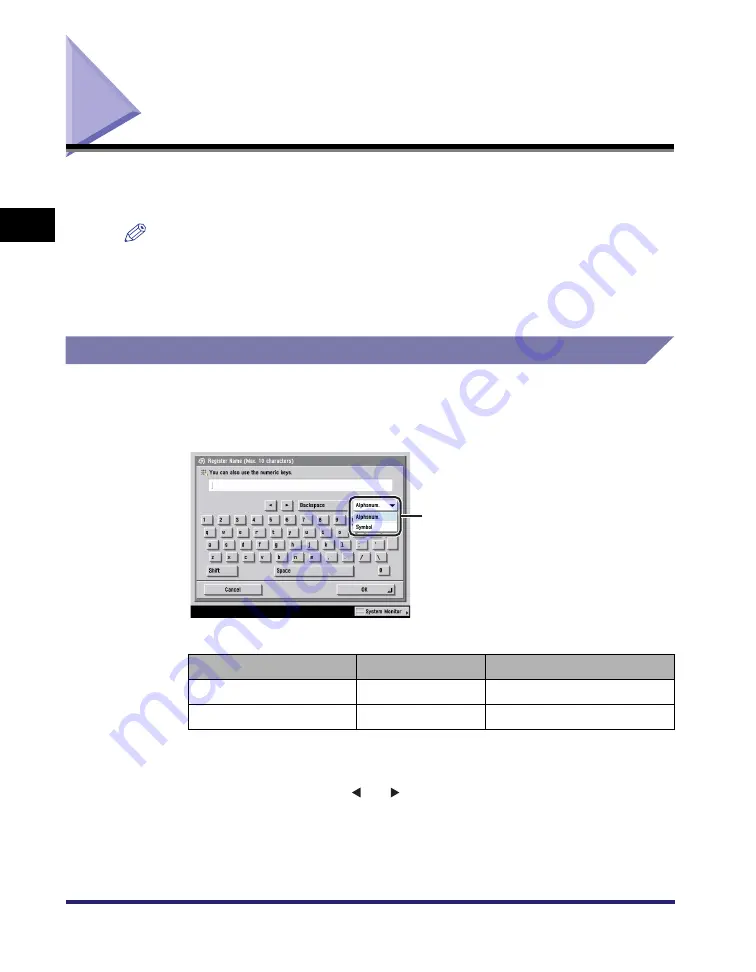

For screens that require alphanumeric entries, enter characters using the keys

displayed on the touch panel display, as shown below.

NOTE

•

When entering characters on the SDL or SSO authentication screen or in MEAP

application functions, the screen you actually see may be different.

•

The available entry modes, and the maximum number of characters that you can enter

vary, depending on the type of entries you are making.

Entering Characters

1

Press the entry mode drop-down list

➞

select the entry mode

➞

enter characters.

The procedure for entering characters with the entry mode is as follows.

To enter uppercase letters, press [Shift].

To enter a space, press [Space].

To move the cursor, press [ ] or [ ].

To switch the entry mode, press the entry mode drop-down list

➞

select the entry

mode

➞

enter the desired characters or symbols.

Entry Mode

Example

Procedure

Alphanum.

Canon

Enter 'Canon'.

Symbol

é

Press [é].

Entry Mode

Summary of Contents for imageRUNNER 5075

Page 2: ......

Page 3: ...imageRUNNER 5075 5065 5055 5050 Reference Guide 0 Ot...

Page 48: ...System Settings 1 28 1 Before You Start Using This Machine...

Page 102: ...Available Paper Stock 2 54 2 Basic Operations...

Page 214: ...Adjusting the Machine 4 68 4 Customizing Settings...

Page 230: ...Priority Printing 5 16 5 Checking Job and Device Status...

Page 257: ...License Registration 6 27 6 System Manager Settings 3 Press OK...

Page 306: ...Restricting Printer Jobs 6 76 6 System Manager Settings...

Page 376: ...Consumables 7 70 7 Routine Maintenance...

Page 500: ...Index 9 22 9 Appendix...

Page 501: ......