Improving the Finish of Booklets

50

imagePRESS C10000VP/C8000VP

imagePRESS C10000VP/C8000VP

51

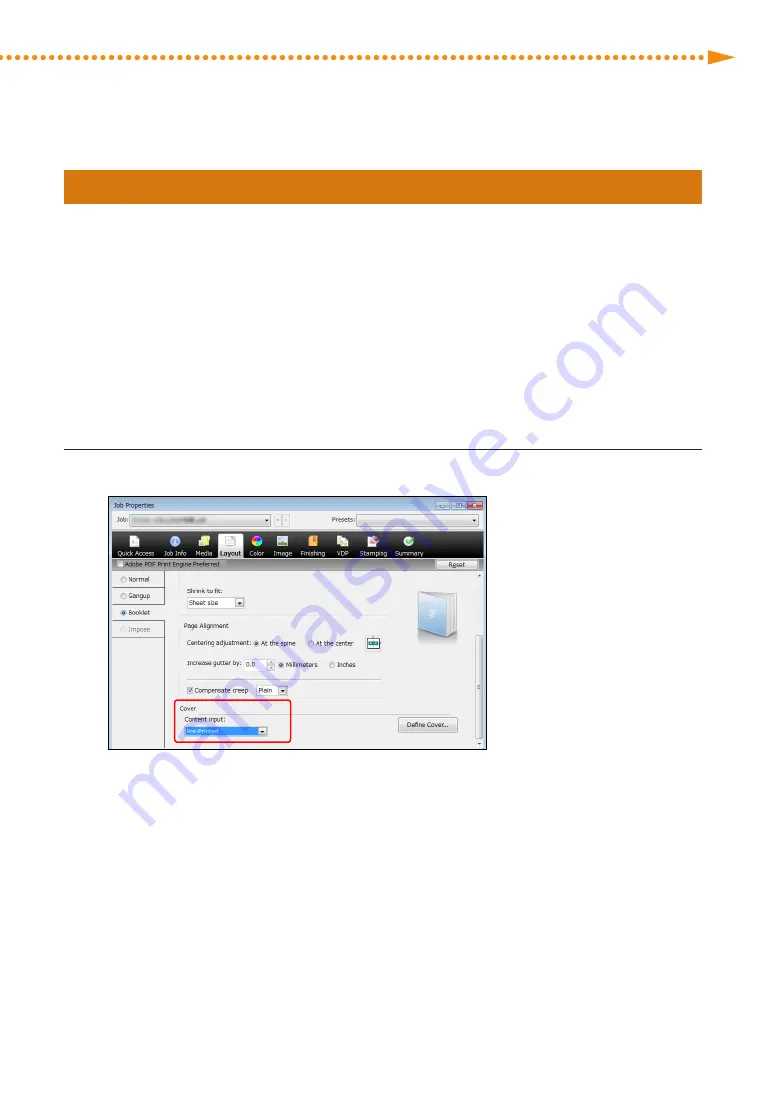

Step 4 Checking the Cover Settings

If you have any of the following problems, confirm that the settings for the cover are appropriate�

• The first page of the main document is printed on the front cover, even though you want to add a front cover using

a pre-printed cover�

• The main document is printed on the inside of the front cover, even though you want the front cover to be blank�

NOTE

When binding a booklet by feeding covers from a different paper source than for the main document, select the

[Media] tab in advance, and then perform settings according to the print status�

▀

Feeding Pre-printed Covers from a Different Paper Source than for the Main Document

1

Confirm <Pre-Printed> is selected from the <Content input> drop-down list for <Cover>�

Summary of Contents for imagePRESS C10000VP

Page 2: ......