2

2

2-97

2-97

Technology > Pickup / Feed System > Pick-up Area Control/Function > Paper Surface Control

Technology > Pickup / Feed System > Pick-up Area Control/Function > Paper Surface Control

LED

Timing to

activate

Timing to

flash

Timing to turn

off the light

Timing to switch

Remaining

level LED

(Green)

When

paper

reaches the

specified

remaining

level

-

Anytime

except when

the light is

activated

Activation →

Extinction

When the deck is open,

when shifting to sleep state

Extinction →

Activation

When the deck is closed

and the paper surface is

detected after the lifter

movement, when recovering

from sleep state

Open

button

(green)

When the

deck is

open

During lifter

movement

when the

deck is open

Anytime

except when

the light is

activated or

flashing

Flashing →

Extinction

When the lifter completes

moving up to the pickup

position

Flashing →

Activation

When the deck is open

while the lifter is moving

Activation →

Extinction

When shifting to sleep state

while the deck is open

Activation →

Flashing

When the lifter is moved

once the deck is closed

Extinction →

Flashing

When the lifter is moved

down once the open button

is pressed

Extinction →

Activation

When the deck is open

once the deck is stopped

Paper

supply

LED

(orange)

-

When

the job is

interrupted

because

of low

remaining

paper level

Anytime

except when

the light is

flashing

Flashing →

Extinction

When paper is supplied,

when job is cancelled

Extinction →

Flashing

When job is interrupted due

to lack of remaining paper

Lock LED

(orange)

During

pickup,

during

preparation

to pick up

-

Anytime

except when

the light is

activated

Activation →

Extinction

When pickup preparation

(floatation movement)

is completed, when the

printer engine is stopped

(e.g. abnormal completion,

shifting to sleep state).

Extinction →

Activation

Preparation to activate

for pickup (floatation

movement) is started

In the case that the foreign particle sensor detects foreign matter in the compartment, the lock

LED, the remaining level LED and the paper supply LED flash at a 500 msec cycle.

Paper can be supplied when in save-energy mode although all LEDs are turned off.

T-2-82

■

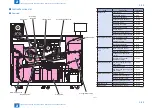

Paper Surface Control

This machine moves the lifter up and down to keep the paper surface at specified height for

smooth pickup.

The up/down movement of the lifter is controlled according to the detection result on the

paper surface.

Detecting the paper surface at 2 locations (paper's lead edge and the trail edge) improves

accuracy and enables high speed feeding.

Paper surface detection at paper's lead edge

Three paper surface sensors detect the height of the paper surface at the lead edge.

Detection timing:

• When the lifter is moved up at power ON or after the deck is closed

• When preparing pickup

• During pickup

• When pickup is complete

Paper surface detection at paper's trail edge

Two trailing edge sensors detect the height of the paper surface at the trail edge.

This function is used accessorily when the paper height cannot be detected at the leading

edge in a case in which the sheet is stuck onto the suction belt, etc.

Detection timing:

• When the lifter is moved up after the deck is closed

• During pickup

Summary of Contents for imagePRESS 1110

Page 242: ...3 3 Periodical Service Periodical Service Periodical service item ...

Page 655: ...5 5 Adjustment Adjustment Overview When replacing parts Major adjustment ...

Page 944: ...8 8 Service Mode Service Mode Overview COPIER FEEDER SORTER BOARD Situation Mode ...

Page 1555: ... Service Tools General Circuit Diagram General Timing Chart Operator Maintenance Appendix ...