GB

MXV, MXV-B Rev6 - Operating Instructions

Page 17 / 136

Provide space around the pump for motor

ventilation, to allow for checking of shaft rotation,

for filling and draining the pump and to allow for

collection of the liquid to be removed

(especially

for draining liquids which are harmful or have to be

removed at temperatures higher than 60 ˚C).

Make sure prolonged accidental leakage of

liquid does not cause damage to persons

or property.

Leakage may develop as a result of surge pressure or

water hammer, erroneous operations (such as failing

to close a plug or valve) or other functional disorders.

Allow for the possibility of channeling away any leaked

liquid or for an automatic drainage system against

flooding.

Mount the pump on a flat horizontal surface (using a

level gauge) such as a solid cement base or a rigid

supporting structure in metal.

To ensure stability, insert, if necessary, small pieces of

calibrated metal plate next to the 4 anchoring screws.

6.5.

Connecting the motor (only MXV(L),

MXV(L)4)

The

MXV(L), MXV(L)4

pumps are designed for use

with standard electric motors with (IEC 34-7) IM V1

construction form and dimensions and output ratings

in accordance with IEC 72.

If a pump is supplied without the motor

, check the

rated power and rpm indicated on the name plate and

technical data given in the data sheet.

ATTENTION

: the motors must have two lifting points

in diametricalIy opposite positions for vertical lifting

with the shaft end downwards (fig.1 b)

Before installation clean the motor shaft extension, the

key and contact surfaces of the flanges to remove any

protective paint, dirt or oxydation.

Lubricate the motor shaft extension with a graphite-

base, dripfree, anti-friction product.

Do not use oil as it can harm the mechanical seal

below (see

section 8.4.

).

With the pump in the vertical position, insert the motor

shaft in the coupling, aligning the key with the key slot

and resting the motor flange on the lantern flange.

Turn the motor, adjusting the position of the terminal

box as required and aligning the holes on the flanges.

ATTENTION

: the 4 flange screws (70.18) with

nut must be uniformly tightened with alternated

crossover tightening procedure in diametrically

opposite positions (see

section 9.1.

).

Before and after tightening the screws (70.18), make

sure the coupling with pump shaft and motor shaft can

be freely turned by hand (remove and then replace the

guard 32.30).

ATTENTION

: for removing or replacing the motor

see

section 8.3.

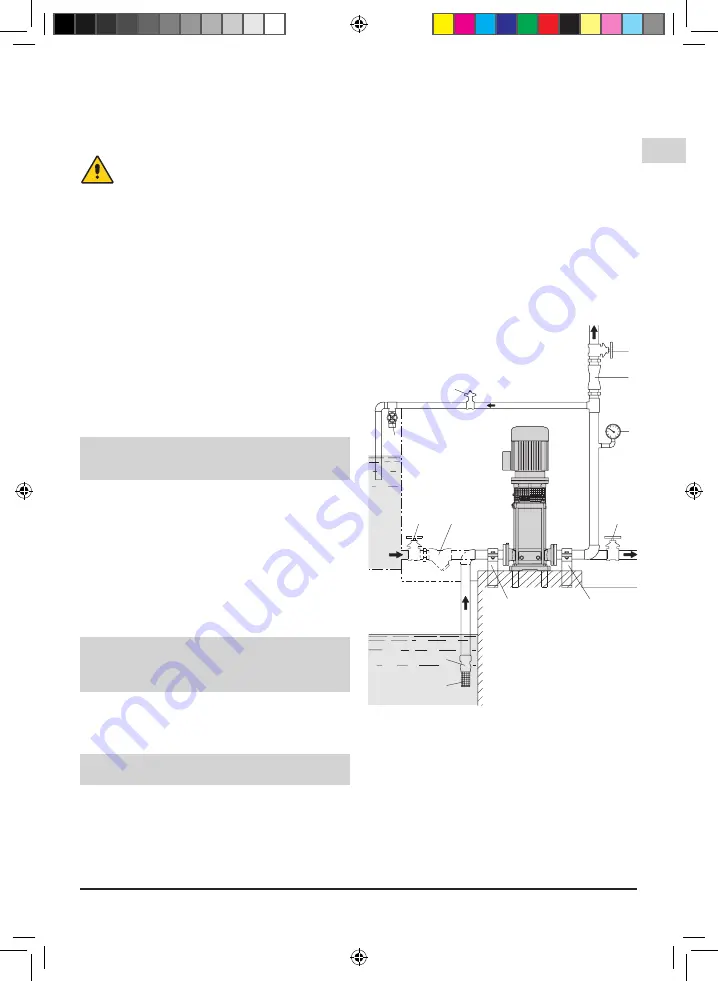

6.6. Pipes

Provide a diameter assuring a liquid flow velocity not

higher than 1.5 m/s for suction, and 3 m/s for delivery.

The pipe diameters must never be smaller than the

pump connection ports.

The arrows on the pump casing (14.00) indicate the

inlet (suction) and outlet (delivery) ports.

Ensure the internal pipe surface is clean before

connection.

Secure all pipes to their rests close to the pump and

connect them so that they are not subjected to stress

and do not transmit vibration or flexion strain to the

pump (see

fig.3

).

Provide for the possibility of draining the pump

without having to drain the entire system.

Install correctly any compensators for absorption of

expansion or impeding noise transmission.

Make sure gaskets do not protrude inside the pipes

for the pump types MXV-B, MXV(L) 25,32,40 and

MXV(L)4 25,32,40 screw the union couplings or the

flanges into the

threaded ports

(ISO 228) by inserting

in the joint a suitable sealing material.

Tighten the pipes or union couplings only to the extent

sufficient to ensure a tight seal. Excessive torque may

damage the pump.

With

flanged ports

make sure the gaskets do not

protrude inside the pipes.

A

B

6

3

5

2

7

4

5

7

1

5

1

5

3.93.113

6.6.1. Suction pipe

When a

pump is located above the water level

(suction lift operation,

fig. 3 A

), fit a foot valve with a

strainer, which must always remain immersed.

The suction pipe must be perfectly airtight and be led

upwards in order to avoid air pockets.

When the

liquid level on the suction side is above

the pump

(inflow under positive suction head,

fig. 3

B

), fit a gate valve.

Follow local specifications if increasing network

pressure.

Install a strainer on the suction side of the pump to

prevent foreign particles from entering the pump.

1. Strainer

2. Foot valve

3. Check valve

4. Bypass valve

5. Gate valve

6. Pressure gauge

7. Supports and clamps for

pipelines

Fig. 3 Systems diagram

A = Suction lift operation

B = Positive suction head operation

MXV, MXV-B Rev6.indd 17

01/10/18 17:06