GRACE3 - SPIRIT3 - MADISON - TABLA - ROXY - ATRIUM - SOLO 5

8

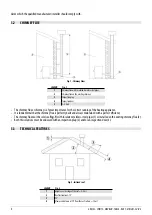

LEGEND

Fig. 6

1

Insulating material

2

Reduction from Ø100 to Ø80 mm

3

Inspection plug

4

Minimum safety distance = 0,5 mt

• Chimney flue installation Ø100/120 mm with an enlarged drilling for pipe transit.

Fig. 7 - Example 2

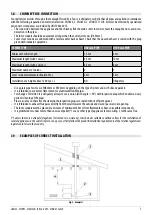

LEGEND

Fig. 7

1

Insulating material

2

Inspection plug

3

Chimney inspection entrance

4

Minimum safety distance = 0,5 mt

5

Inclination ≥ 3°

6

Level section ≤ 1 mt

• Old chimney flue with an inserted pipe of minimum Ø100/120 mm and with an external door which enables the chimney

cleaning.

Fig. 8 - Example 3