Blow Applicator with Swing Cylinder

cab - Produkttechnik GmbH & Co KG

17

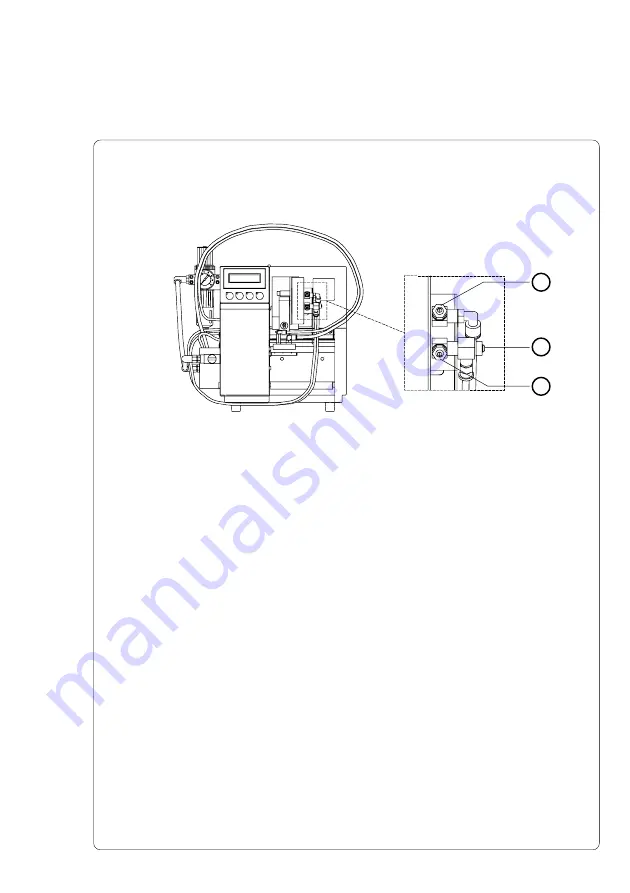

Throttle Valves at the Cylinder

1

2

3

Fig. 5.2b Throttle Valves at the Cylinder

The setting of the cylinder can be regulated via two throttle valves (

1,

3

). Those valves regulate the speed with which the compressed air

escapes the two air containers.

The valves are adjustable by turning the throttle screws. Turning

clockwise will close the valves.

A wider opening of the bottom valve (

3

) speeds up the pad moving

from the starting position to the labelling position, a wider opening of

the top valve (

1

) accelerates the return movement.

A third throttle valve (

2

) limits the speed of the compressed air

streaming into the bottom air container. By switching the machine on

this valve damps the first movement of the pad into the starting

position. At this time the top air container is empty, therefore, the

setting of the top throttle valve (

1

) is ineffective to damp this move-

ment.