INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 21 of 66

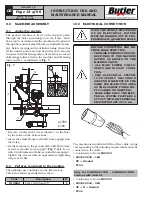

12.5.1 Tools rotation

THE FOLLOWING OPERATIONS

MUST BE CARRIED OUT WITH

THE TOOLS HEAD IN “OFF- WORK”

POSITION.

The machine is equipped with a Quick-fit tool, remark-

ably facilitating the tools unit rotation operations. Here

follows the description of these operations.

In order to rotate the tool head (

Fig.

_

17 ref.

_

1

) just

push the unlocking lever (

Fig.

_

17 ref.

_

3

) towards

the tool arm (

Fig.

_

17 ref.

_

2

). When the new working

position of the head is reached (

Fig.

_

17 ref.

_

1

) the

lever (

Fig.

_

17 ref.

_

3

) automatically inserts locking

its rotation.

2

3

180°

1

Fig.

_

17

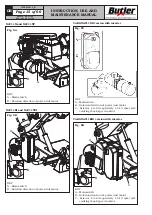

12.6 Tubeless tyres

12.6.1 Bead breaking

NEVER PLACE ANY PART OF YOUR

BODY BETWEEN THE TOOL UNIT

AND THE TYRE.

THROUGHOUT TYRE MOUNT-

ING/DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CEN-

TRING CHUCK CLAMPING PRES-

SURE IS CLOSE TO THE MAXIMUM

OPERATING VALUE (150 BAR).

A.

Lock the wheel on the mandrel as described in the

previous paragraph.

B.

Remove all balancing weights from the rim. Extract

the valve and let air out of tyre.

C.

Move to work position

C

(

Fig.

_

6

).

D.

Lower tool holder arm into work position (coupling

lever introduced, see

Fig.

_

16

).

ALWAYS MAKE SURE THAT THE

ARM IS CORRECTLY HOOKED TO

CARRIAGE.

E.

Place as shown in

Fig.

_

18

the beading disc (

Fig.

_

18

ref.

_

1

) by means of the relevant handle control; the

outer profile of the rim (

Fig.

_

18 ref.

_

2

) must almost

touch the beading disc.

Fig.

_

18

3

2

1

THE BEADING DISC MUST NOT

EXERT PRESSURE ON THE RIM

BUT ON THE TYRE BEAD.

NAV11N - NAV11NT

NAV11EI - NAV11TEI

7505-M001-3_B