INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 20 of 66

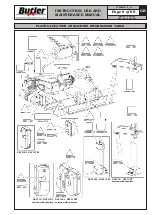

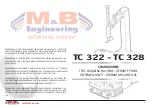

In “out of work” position (

Fig.

_

15 ref.

_

1

): the tool

holder arm is in vertical position and has to be brought

in this position every time it is not in use and in order

to be shifted from one tyre bead side to another, dur-

ing working phase.

1

Fig.

_

15

The tool holder arm, shifts from “off-work” position to

“working” position and vice versa manually.

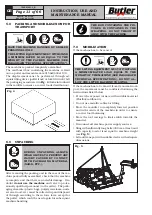

IN WORKING POSITION, THE

COUPLING LEVER (FIG. 1 REF. 8)

MUST BE CORRECTLY HOOKED

HOOKED TO THE TOOL CAR-

RIAGE CLAMPING PROFILES (SEE

FIG. 16).

When the tool holder arm is in “off-work” position, it

can be laterally shifted in manual mode in one of the

two pre-set positions on the carriage, so that it can

better positioned (according to the operations to be

performed afterwards) before it reaches “working”

position again.

Fig.

_

16

UNLOCK

POSITION

CLAMPING

POSITION

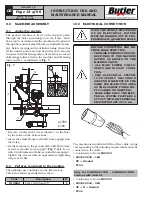

DURING ALL TYRES MOUNTING AND DE-

MOUNTING OPERATIONS, THE SELF-CEN-

TRING CHUCK ROTATION SPEED CAN BE

DOUBLED BY ROTATING THE SELECTOR (FIG.

8C-8D REF. C). LOW SPEED IS RECOMMENDED

FOR WHEELS WITH GREAT DIAMETER AND

WEIGHT.

THE CAREFUL LUBRICATION OF THE TYRES

BEADS IS RECOMMENDED, IN ORDER TO PRO-

TECT THEM FROM POSSIBLE DAMAGES AND

TO FACILITATE MOUNTING AND DEMOUNTING

OPERATIONS.

12.5 Functioning of tool holder arm

During the working phases, the tool holder arm can

maintain two firm positions, that is:

1) “Working” position;

2) “Out of work” position.

In “working” position (

Fig.

_

14 ref.

_

1

) the tool holder

arm is lowered towards the mandrel and from this

position it executes the various tyre bead breaking,

demounting and mounting operations.

1

Fig.

_

14

7505-M001-3_B

NAV11N - NAV11NT

NAV11EI - NAV11TEI