134

of 216

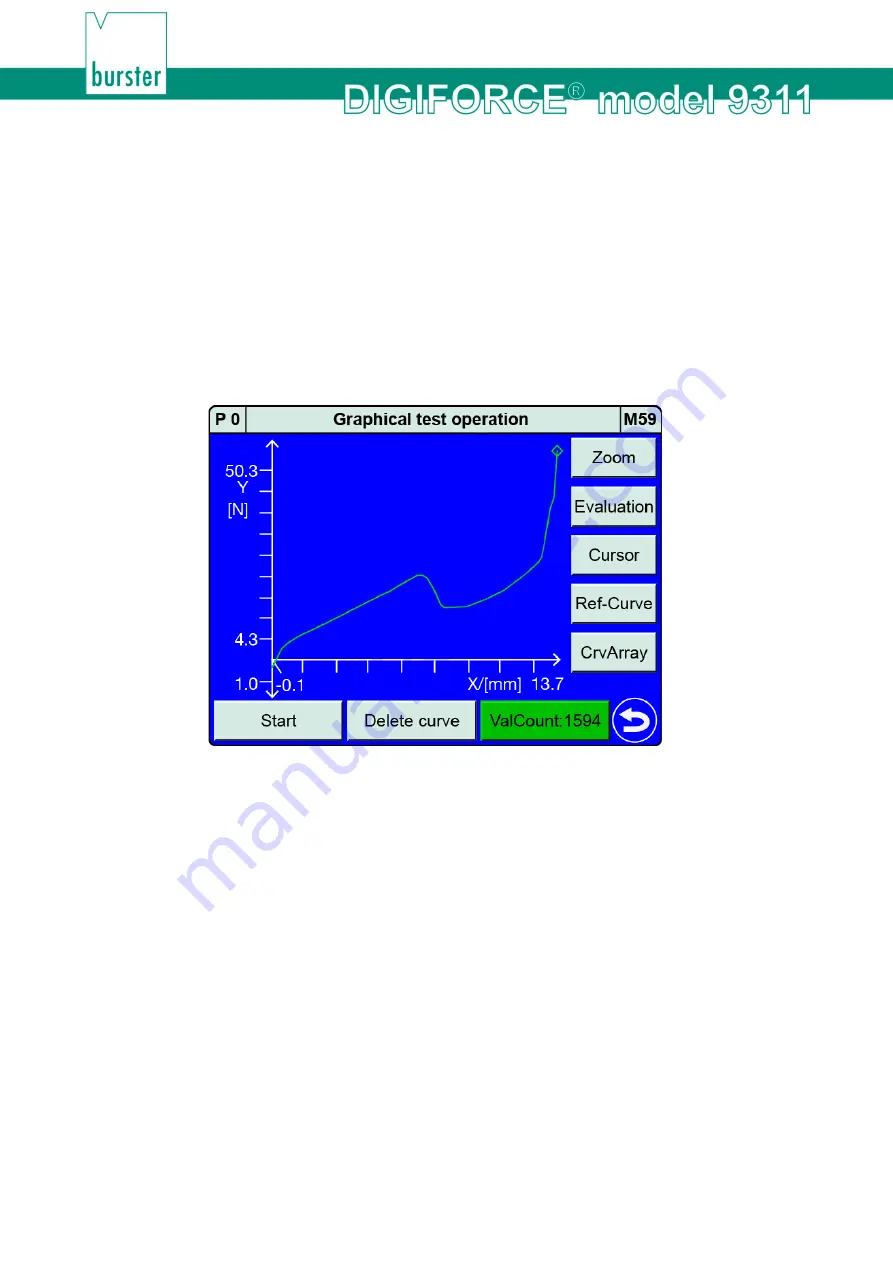

6.3.5 Graphical test operation

In the "Graphical test operation" menu (M59) you can perform measurements in one or more

measurement programs and use the recorded measurement curve(s) to define the graphical evaluation

elements such as "Window", "Trapezoid", "Threshold" and "Envelope". The 10 most recent measurement

results from each measurement program are saved. You can select

[CrvArray]

to display this set of

recorded measurement curves as a curve array. When calculating an envelope, the DIGIFORCE

®

9311

uses these measurement curves as the basis for generating the "Envelope".

Note:

Note that on activation of the "IN_AUTO" control input, the "Graphical test operation" menu

(M59) will close automatically and the DIGIFORCE

®

9311 will switch to measurement mode. In

"Graphical test operation", the other PLC I/O control signals respond in exactly the same way as

in measurement mode, and the online switching points are also active.

Diagram 57: Graphical test operation

The following functions are available in the "Graphical test operation" menu (M59):

•

Run measurements

•

Adjust the scale of the measurement curve

graph

[Zoom]

•

Configure evaluation elements

[Evaluation]

•

Take readings from the measurement

curve using the

[Cursor]

•

Enable a measurement curve as the

reference curve

[Ref-Curve]

•

Show/Hide the curve array view

[CrvArray]

•

External control (start measurement,

change program, tare, sensor test, ...)

Summary of Contents for DIGIFORCE 9311

Page 3: ...3of 216...