8

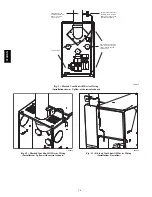

Step 4 — Venting

Venting of furnace should be to the outside and in accordance with

local codes or requirements of local utility.

OIL--FIRED APPLIANCES SHALL BE CONNECTED TO

FLUES HAVING SUFFICIENT DRAFT AT ALL TIMES TO

ENSURE SAFE AND PROPER OPERATION OF APPLIANCE.

For additional venting information, refer to ANSI/NFPA 211

Chimney, Fireplaces, Vents, and Solid Fuel Burning Appliances

and/or CSA B139 Installation Code.

This furnace is certified for use with Type “L” vent (maximum flue

gas temperature 575

_

F/302

_

C).

Vent System Inspection

Before furnace is installed, it is highly recommended that any

existing vent system be completely inspected.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury

or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into operation,

while all other appliances connected to the venting system are

not in operation:

1. Seal any unused openings in venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the NFPA31, Installation of Oil Burning

Equipment and the Canadian Standard B140.4 Oil Fired Warm

Air Furnaces.

Determine that there is no blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

3. As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other spaces

of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they are operating at

maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so appliance is

operating continuously.

7. Test for spillage from draft--hood equipped appliances at the

draft--hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle.

8. If improper venting is observed during any of the above

tests, the venting system must be corrected in accordance with

the NFPA31, Installation of Oil Burning Equipment and the

Canadian Standard B140.4 Oil Fired Warm Air Furnaces.

9. After it has been determined that each appliance connected

to the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace dampers,

and any other gas--fired burning appliance to their previous

conditions of use.

!

WARNING

For any chimney or vent, this should include the following:

1. Inspection for any deterioration in chimney or vent. If

deterioration is discovered, chimney must be repaired or

vent must be replaced.

2. Inspection to ascertain that vent system is clear and free of

obstructions. Any blockage must be cleared before

installing furnace.

3. Cleaning chimney or vent if previously used for venting a

solid fuel burning appliance or fireplace.

4. Confirming that all unused chimney or vent connections are

properly sealed.

5. Verification that chimney is properly lined and sized per the

applicable codes. (Refer to list of codes in Safety

Considerations section.)

Masonry Chimneys

This furnace can be vented into an existing masonry chimney. This

furnace must not be vented into a chimney servicing a solid fuel

burning appliance. Before venting furnace into a chimney, the

chimney MUST be checked for deterioration and repaired if

necessary. The chimney must be properly lined and sized per local

or national codes.

If furnace is vented into a common chimney, the chimney must be

of sufficient area to accommodate the total flue products of all

appliances vented into chimney.

The following requirements are provided for a safe venting system:

1. Be sure that chimney flue is clear of any dirt or debris.

2. Be sure that chimney is not servicing an open fireplace.

3. Never reduce pipe size below the outlet size of furnace. (See

Fig. 2.)

4. All pipe should be supported using proper clamps and/or

straps. These supports should be at least every 4 ft. (1.2 M)

5. All horizontal runs of pipe should have at least 1/4 in. (6

mm) per ft. (.3 M) of upward slope.

6. All runs of pipe should be as short as possible with as few

turns as possible.

7. Seams should be tightly joined and checked for leaks.

8. The flue pipe must not extend into chimney but be flush

with inside wall.

9. The chimney must extend 3 ft. (.9 M) above highest point

where it passes through the roof of a building and at least 2

ft. (.61 M) higher than any portion of a building within a

horizontal distance of 10 ft. (3.0 M) It shall also be extended

at least 5 ft. (1.5 M) above highest connected equipment

flue collar.

10. Check local codes for any variance.

Step 5 — Factory--Built Chimneys

Listed factory--built chimneys may be used. Refer to chimney

manufacturer’s instructions for proper installation.

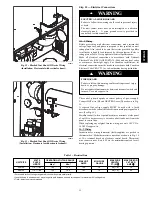

UNIT COMPONENT HAZARD

Failure to follow this caution may result in unit component

damage.

This burner is shipped with the oil pump set to operate on a

single

line system. To operate on a

two--line

system the

by--pass plug must be installed. Do not operate a

single

line

system with the by--pass plug installed. Operating a

single

line system with the by--pass plug installed will result in

damage to the pump shaft seal. Pump pressure must be set at

time of burner start--up. A pressure gauge is attached to the

PRESSURE

PORT

for pressure readings. Two

PIPE

CONNECTORS

are supplied with the burner for

connection lines to burner pipe connectors. All pump port

threads are

British Parallel Thread

design. Direct

connection of NPT threads to the pump

will damage

the

pump body. Riello manometers and vacuum gauges

do not

require any adapters, and can be safely connected to the

pump ports. An NPT (metric) adapter (Part no. N05F017)

must be used when connecting other gauge models.

CAUTION

!

374RAN