-52-

24.

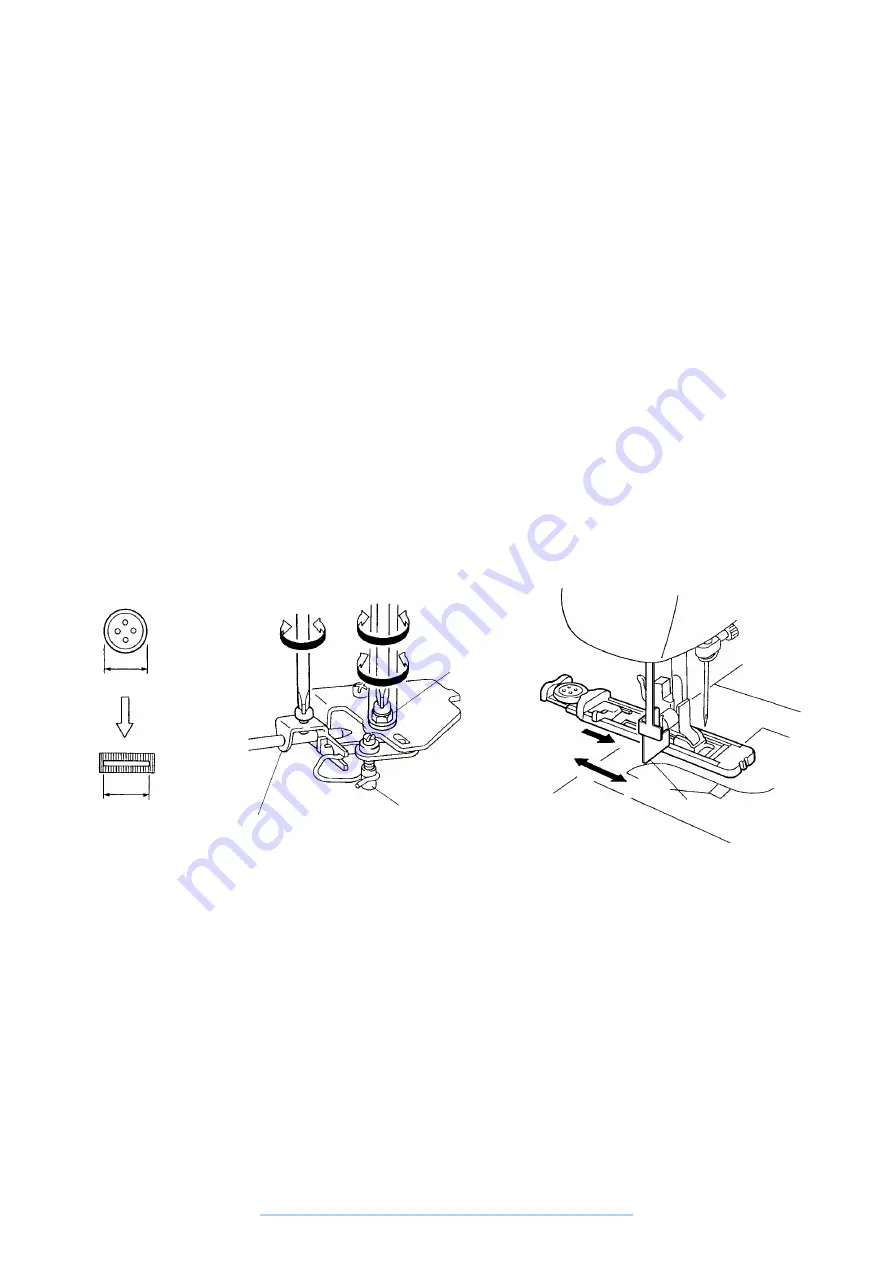

BUTTON HOLE STITCH BUTTON HOLE LENGTH

(XL-6060, XL-6050 Series only)

STANDARD

When a button hole is sewn using a 20 mm button, the button hole length should be sewn 21-23 mm. The BH

operation should be 0.5-1.1 N (50-110 gf) on the return side.

ADJUSTMENT

1.

Loosen the BH change arm set screw.

2.

Adjust according to the arrow mark 2 on the BH lever.

3.

Tighten the BH change arm set screw.

4.

Loosen the screw securing the eccentric nut.

5.

Turn the eccentric nut and align with 0.5-1.1 N (50-110 gf) on the BH lever return side. (The adjustment

should be made within 1/2 rotation of the eccentric nut.)

6.

Tighten the screw securing the eccentric nut.

* Adjust the BH lever changing timing with the BH notch adjustment screw.

21-23 mm

20 mm

Eccentric nut

BH change arm

BH notch adjustment screw

0.5-1.1 N

(50-110 gf)

Shorter

BH lever

Longer

www.promelectroavtomat.ru

Summary of Contents for XL-6040

Page 1: ... 6 2001 www promelectroavtomat ru ...

Page 3: ... 1 I 1 MECHANICAL CHART 2 2 POWER TRANSMISSION CHART 3 www promelectroavtomat ru ...

Page 4: ... 2 1 MECHANICAL CHART www promelectroavtomat ru ...

Page 29: ... 27 2 LEAD WIRES ARRANGEMENT www promelectroavtomat ru ...

Page 61: ...XL 6060 Series XL 6050 Series XL 6040 Series H1040194 www promelectroavtomat ru ...