-46-

18.

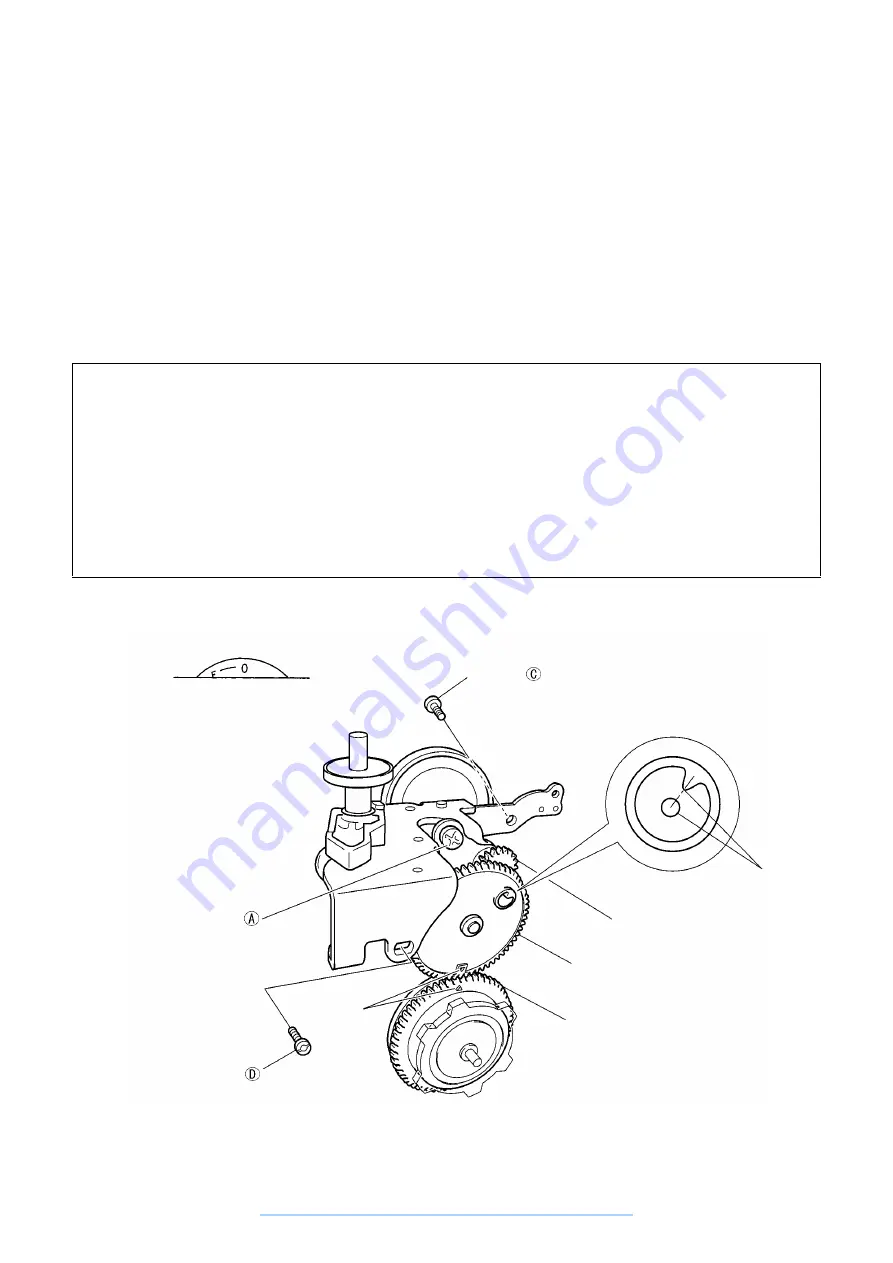

FEED BRACKET INSTALLATION POSITION

STANDARD

When the feed dial is set to 0, the feed dial gear and idle gear and feed cam alignment marks should match.

ADJUSTMENT

1.

Turn the feed dial to the 0 position.

2.

Check that the feed dial gear alignment mark and idle gear alignment mark match.

3.

Check that the idle gear alignment mark and feed cam alignment mark match.

4.

Install with the two screws.

Assembly Points

Tighten the feed bracket assembly screws in the order (C) (D).

Adjustment Points

2.

If the feed dial gear alignment mark and idle gear alignment mark do not match, remove the idle gear lock

rating, move the gear meshing to lineup the alignment marks, then reinstall the lock ring.

Be careful about backlash between the feed dial gear and idle gear and the feed cam.

*

If the backlash is too small, the feed dial moves sluggishly.

If the backlash is too large, the intended feed is not achieved.

To adjust the backlash, loosen the screw (A), move the idle gear left and right, then after the adjustment is

complete, tighten the screw (A).

Alignment

mark

Screw

Screw

Screw

Alignment mark

Feed cam

Idle gear

Feed dial gear

www.promelectroavtomat.ru

Summary of Contents for XL-6040

Page 1: ... 6 2001 www promelectroavtomat ru ...

Page 3: ... 1 I 1 MECHANICAL CHART 2 2 POWER TRANSMISSION CHART 3 www promelectroavtomat ru ...

Page 4: ... 2 1 MECHANICAL CHART www promelectroavtomat ru ...

Page 29: ... 27 2 LEAD WIRES ARRANGEMENT www promelectroavtomat ru ...

Page 61: ...XL 6060 Series XL 6050 Series XL 6040 Series H1040194 www promelectroavtomat ru ...