III-23

4.2

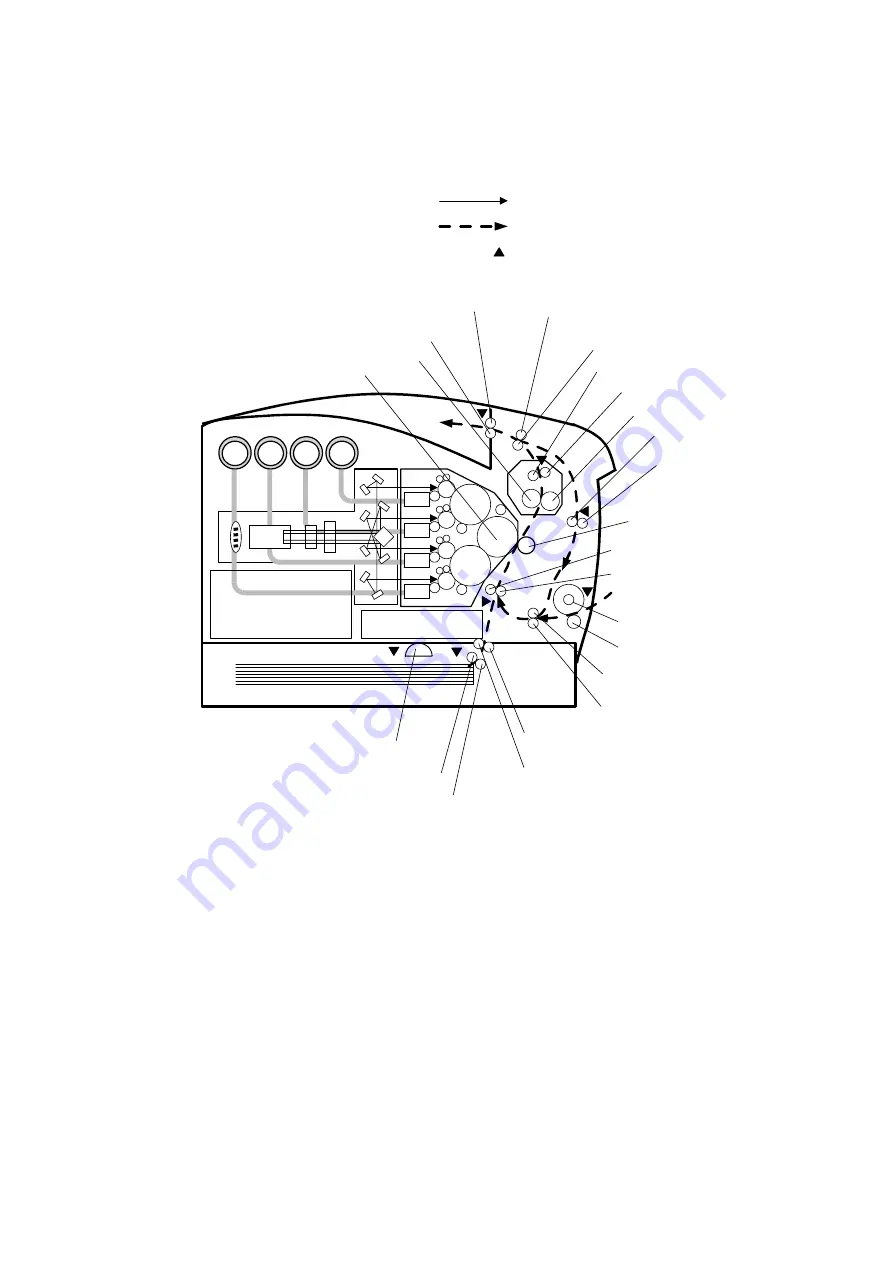

Layout of Paper Transfer Route

ROLL ASSY FEED

(PICK UP ASSY 1T)

ROLL ASSY(Cassette)

ROLL ASSY(PICK UP ASSY 1T)

ROLL ASSY TURN

(PICK UP ASSY 1T)

CHUTE ASSY TURN

ROLL ASSY FEED

ROLL ASSY RETARD

ROLL TURN

ROLL PINCH TURN

Regi Roll

Metal Roll

ROLL PINCH DUP

ROLL DUP

Transfer Roll Cartridge

IDT2

Fuser Belt

Heat Roll

ROLL ASSY EXIT

Pinch Roll

ROLL MID

ROLL EXIT

ROLL PINCH EXIT

ROLL PINCH

: Laser beam

: Paper transfer

: Paper sensors

Fig.3-33

Summary of Contents for HL-4000CN

Page 22: ...CHAPTER I SPECIFICATIONS ...

Page 52: ...CHAPTER II INSTALLATION ...

Page 76: ...CHAPTER III STRUCTURE OF SYSTEM COMPONENTS ...

Page 129: ...CHAPTER IV ASSEMBLY DISASSEMBLY ...

Page 132: ...2 5 21 Roll ASSY IV 74 2 5 22 Cassette ASSY front IV 74 2 5 23 Holder retard IV 75 ...

Page 208: ...CHAPTER V TROUBLESHOOTING ...

Page 281: ...V 71 9 4 Straightness Fig 5 13 9 5 Magnification Error Fig 5 14 9 6 Registration Fig 5 15 ...

Page 282: ...V 72 9 7 Guaranteed Printing Area Fig 5 16 ...

Page 295: ...CHAPTER VI 5 06 ...

Page 336: ...CHAPTER VII 3 8 3 211 725 2 7 216 ...

Page 341: ...VII 4 P J LAYOUT DIAGRAM 2 1 IOT Top ...

Page 342: ...VII 5 2 2 IOT Front RH ...

Page 343: ...VII 6 2 3 MCU and HVPS PWB ESS PWB ...

Page 344: ...VII 7 2 4 Tray1 ...

Page 345: ...VII 8 2 5 2 Tray Module ...