5-16

Confidential

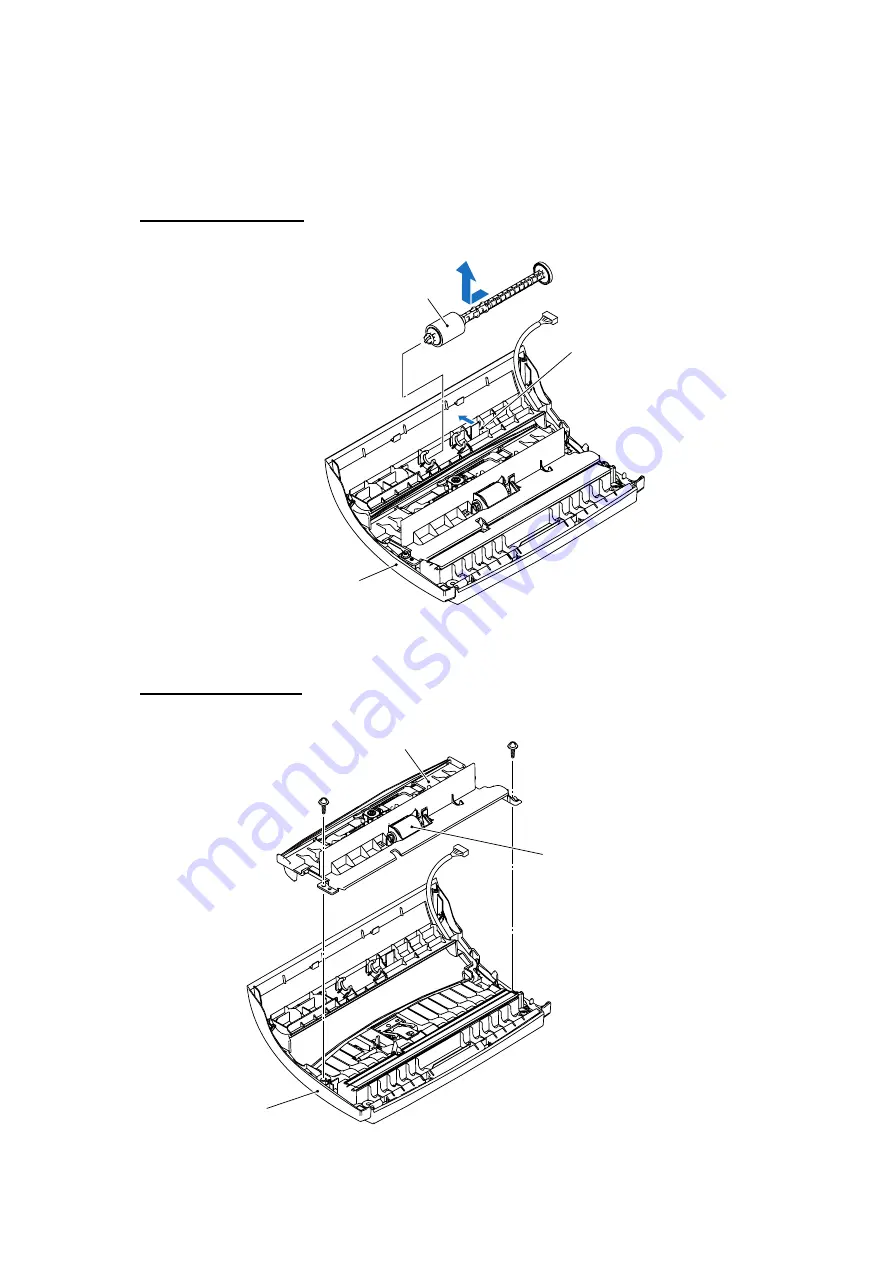

5.1.5 Disassembly of the Top Cover Sub ASSY

(Paper separation roller, document chute ASSY, document separation roller, ADF parts,

white-level reference film, control panel ASSY, and document rear sensor actuator)

Paper separation roller

(1) Lightly press the lock arm, slide the paper separation roller to the left and lift it up.

Paper

separation

roller

Top

cover

sub

ASSY

(placed

upside

down)

(Front)

Lock

arm

Reassembling Note:

When mounting the paper separation roller, make sure that the panel-main

harness (upper) has been routed on the top cover as shown

Document chute ASSY

(2) Remove the two screws and take the document chute ASSY out of the top cover.

Document

chute

ASSY

Top

cover

(placed

upside

down)

(Front)

Document

separation

roller

Taptite, cup B M3x8

Summary of Contents for FAX-545

Page 7: ...Confidential CHAPTER 1 PARTS NAMES FUNCTIONS ...

Page 18: ...Confidential CHAPTER 2 SPECIFICATIONS ...

Page 26: ...Confidential CHAPTER 3 THEORY OF OPERATION ...

Page 33: ...3 6 Confidential Not provided on the FAX T102 Sensors and Actuators Locations ...

Page 35: ...Confidential CHAPTER 4 TRANSFER OF DATA LEFT IN THE MACHINE TO BE SENT FOR REPAIR ...

Page 38: ...Confidential CHAPTER 5 DISASSEMBLY REASSEMBLY AND LUBRICATION ...

Page 81: ...5 41 Confidential 5 1 17 Routing of the Harnesses 0 11 ...

Page 83: ...Confidential CHAPTER 6 ADJUSTMENTS AND UPDATING OF SETTINGS REQUIRED AFTER PARTS REPLACEMENT ...

Page 88: ...Confidential CHAPTER 8 MAINTENANCE MODE ...

Page 95: ...8 6 Confidential Scanning Compensation Data List a b c d e f g h i j k ...

Page 113: ...Confidential CHAPTER 9 ERROR INDICATION AND TROUBLESHOOTING ...

Page 116: ...9 2 Confidential ...

Page 117: ...9 3 Confidential ...

Page 185: ......

Page 186: ......

Page 187: ......

Page 189: ......

Page 190: ......

Page 191: ......

Page 192: ......

Page 193: ......

Page 194: ......

Page 198: ...Confidential August 08 SM FAX034 8X4600 7 Printed in Japan ...