2-72

Confidential

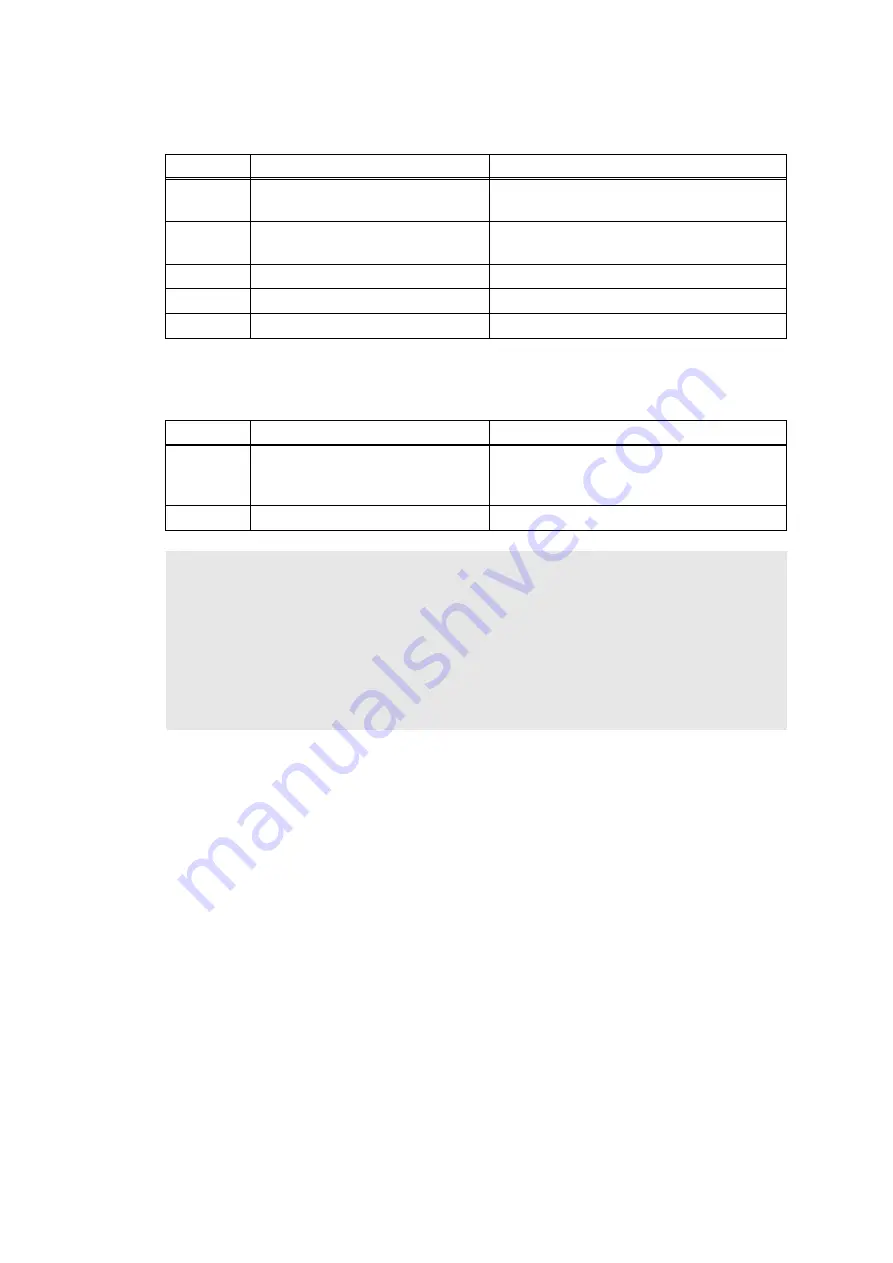

Error code E900

An error occurred while initializing the NFC.

Error code F900

The spec code was not entered correctly.

Step

Cause

Remedy

1

Connection failure of the panel

flat cable

Reconnect the panel flat cable.

2

Connection failure of the NFC flat

cable

Reconnect the NFC flat cable.

3

Panel PCB failure

Replace the panel PCB ASSY.

4

NFC PCB failure

Replace the NFC PCB ASSY.

5

Main PCB failure

Replace the main PCB ASSY.

Step

Cause

Remedy

1

The power was turned OFF while

function code 74 was running.

Reenter the spec code. (Refer to

Configure for country/region and model

(Function code 74)” in Chapter 5

2

Main PCB failure

Replace the main PCB ASSY.

Memo:

• For non touch panel models, simultaneously pressing the [*] and the [#] clears the error

display under error code F900 display, and then the maintenance mode can be selected

again.

• For touch panel models, pressing the [*] or the [#] clears the error display under error

code F900 display, and then the maintenance mode can be selected again.

• For DCP models, press the [

▲

] or the [

▼

] under error code F900 display to select the

maintenance mode.

Summary of Contents for DCP-2537DW

Page 50: ...2 10 Confidential MP models Fig 2 6 Feed from MP tray Eject to back side Back side Front side ...

Page 51: ...2 11 Confidential 2 2 2 Scanner part Fig 2 7 Document feed path ...

Page 300: ...5 28 Confidential Print adjustment test pattern Fig 5 11 ...

Page 311: ...5 39 Confidential Print pattern Fig 5 16 W 100 K 1 K 100 Total Lattice K 5 ...

Page 316: ...5 44 Confidential Test pattern Fig 5 19 ...

Page 332: ...5 60 Confidential ...