25

•

Avoid the installation in places where there are collective ventilation pipes, hoods with or without extractor, B type gas equipments,

heat pumps or equipments that can cause that the draw is not good if they are used at the same time.

•

Make sure that the smoke duct and the pipes used for the stove are suitable for the operation of the insert.

•

Make sure that all the equipment has their own smoke duct. Do not use the same duct for several equipment.

We recommend that you call your fitter in order to check both the chimney as well as the air flow for the combustion.

5.1

SAFETY MEASURES

During the installation of the equipment, there are risks to be taken into account, so you should follow the next safety measures:

a.

Keep any flammable or heat sensitive materials (furniture, curtains, and clothing) at a minimum distance of about 150cm.

b.

If the equipment is installed on a floor which is not completely refractory or inflammable it is necessary to replace this part or introduce

a fire-resistant base.

c.

Do not place the thermo-stove near combustible walls or likely to be

affected by a thermal shock.

d.

The stove should only be used when the ash pan is inserted.

e.

It is recommended to install carbon monoxide detector (CO) in the

room where the equipment is installed.

f.

If you need a longer wire than the provided use it always with an

earthed plug.

g.

Do not install the stove in a bedroom.

h.

The appliance should never be turned on in the presence of

emission of gases or vapours (e.g., linoleum glue, gasoline, etc).

Do not place nearby flammable materials.

i.

Solid combustion residues (ashes) should be collected in an airtight

container and resistant to fire.

j.

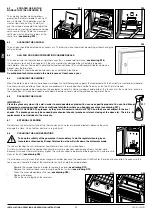

It is necessary to keep a safe distance when they are installed in

spaces where materials are susceptible of being flammables, either

the constructions materials or different materials that surround the

thermo-stove (

see drawing D7

).

References

Flammable items

Non-flammable items

A

1500

800

B

1500

150

C

1500

400

WARNING!! It is noted that both the thermo-stove and the glass get very hot and should not be touched.

In case of fire in the thermo-stove or smoke duct:

a.

Close the loading door.

b.

Put the fire out by using carbon dioxide extinguishers (CO2 powder).

c.

Request for the immediate intervention of the fire-fighters.

DO NOT PUT OUT THE FIRE WITH WATER.

UK HETAS

regulations as stated in document J combustion appliances and fuel storage systems.

Whilst the document J gives the guidance for compliance, the installer must interpret the guidance from manufactures for the correct

installation of their equipment in order to be compliant with UK building regulations and the guidance in this document.

The points which we discussed at the training were:

1) The document J requires the installer to provide adequate ventilation for combustion if room air is being used for combustion and for

heat dissipation. So the room should always be adequately ventilated unless you wish to specify additional requirements. It would be possible

to specify “in accordance with document J sections 1.” In the Bronpi manual if you wanted to make sure that an installer maintains sufficient

ventilation for the boilers.

So particular to the Bronpi boilers we think the manufacturer’s recommendations should include the following:

2) If the flue is to pass straight through the wall then it must run horizontally and connect with a double skin 90* Tee on the outside. This

horizontal section must not exceed 500mm in length. Do not run the first length of flue at 45* through the wall. Alternatively, the first run may

run from a 90* Tee vertically to a maximum height of 2m before connecting to a double skin insulated flue (but within 450mm of the ceiling)

or exiting the building on a 45* through the wall after rising above the boiler to a height which will allow draught stabilisers and inspection

hatches to be mounted. Any bends should have an analyser port so that an installer can put a gas analyser probe to check flue gases.

3) Distance to non combustible materials.

The diagram below illustrates that distances to non combustible materials can be reduced to a minimum of 150mm. However, the practical

access required to service and maintain the boilers is not respected in that case so minimum access distances for service to rear and side

should be specified by Bronpi for the practical maintenance of the boilers.

20 cm

A

B

C

80-120 cm

2

D7

Floor covering

EN

INSTALLATION, OPERATING AND SERVICING INSTRUCTIONS

HYDRO SERIES

Summary of Contents for Dama Hydro

Page 107: ...106 12 1 DAMA H FT ...

Page 109: ...108 12 2 LETICIA H FT ...

Page 111: ...110 12 3 REYNA H FT ...